Evaluation of protective effect of deposits formed by naphthenic corrosion and sulfidation on carbon steel and steel 5Cr-0.5Mo exposed in atmospheric distillation fractions

DOI:

https://doi.org/10.3989/revmetalm.092Keywords:

High temperature corrosion, Iron sulfides, Naphthenic acids, Naphthenic corrosionAbstract

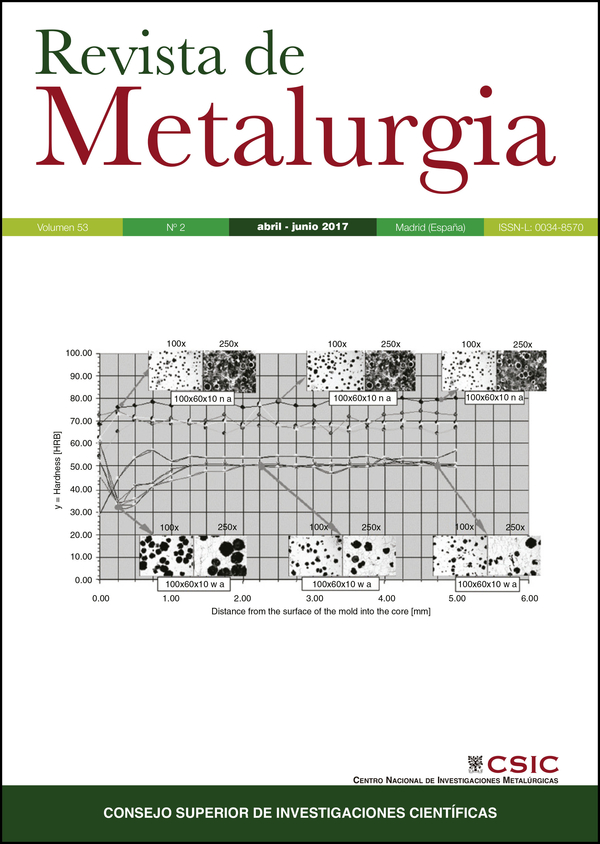

Refining of so-called opportunity crude oils with a high level of naphthenic acids and sulfur compounds has been increasing interest due to limited availability of light crude oils, however, considerable corrosive effects in the processing to high temperature on pipes and distillation towers mainly by the attack of naphthenic acids and sulfur compounds; sulfur compounds could be corrosive or can reduce the attack of naphthenic acids due to the formation of sulfides layers on the metal surface. In this work was evaluated the performance of deposits formed on the surface of carbon steel AISI SAE 1020 and 5% Cr-0.5% Mo steel exposed in crude oil fractions obtained from atmospheric distillation tower. For this, gravimetric tests were performed in dynamic autoclave using metal samples pre-treated in a crude oil fraction obtained from the atmospheric distillation tower of the Crude Distillation Unit (CDU) # 1 in order to form layers of sulfides on the surface of the two materials and subsequently to expose pre-treated and non-pretreated samples in two different crude oil fractions obtained from atmospheric distillation tower of Crude Distillation Unit (CDU) # 2. The evaluation showed that the samples pretreated decreased tendency to corrosion by naphthenic acids and sulfidation compared to untreated samples.

Downloads

References

API (2000). Risk-Based Inspection: Base Resource Document. Vol. 581, American Petroleum Institute, Washington D.C., USA.

ASTM D664 (2011). Standard Test Method for Acid Number of Petroleum Products by Potentiometric Titration. ASTM International, West Conshohocken, USA.

ASTM G1 (2011). Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens. ASTM International, West Conshohocken, USA.

ASTM D5453 (2012). Standard Test Method for Determination of Total Sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel, and Engine Oil by Ultraviolet Fluorescence. ASTM International, West Conshohocken, USA.

ASTM G31 (2012). Standard Guide for Laboratory Immersion Corrosion Testing of Metals. ASTM International, West Conshohocken, USA.

ASTM E415 (2014). Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry. ASTM International, West Conshohocken, USA.

Bota, G., Qu, D., Nesic, S., Wolf, A. (2010). Naphthenic acid corrosion of mild steel in the presence of sulfide scales formed in crude oil fractions at high temperature. Conference & Expo, Corrosion 2010, Nace International (ID 10353), Texas, USA.

Bota, G., Nesic, S. (2013). Naphthenic acid challenges to iron sulfide scales generated in-situ from model oils on mild steel at high temperature. Corrosion 2013, Nace International (ID 2512), Florida, USA.

Delfino, C.A., Lires, O.A., Rojo, E.A. (1987). Protección de aceros al carbono en plantas G.S.V. Estudio de la influencia de la presión sobre la formación de capas protectoras de sulfuros. Comisión Nacional de Energía Atómica (CNEA), Argentina. http://www.iaea.org/inis/collection/NCLCollectionStore/_Public/23/046/23046939.pdf.

Dettman, H.D., Li, N., Luo, J. (2009). Refinery corrosion organic acid structure, and Athabasca bitumen. Corrosion 2009, Nace International (ID 09336), Atlanta, USA. PMCid:PMC3991472

Groysman, A., Brodsky, N., Penner, J., Goldis, A., Savchenko, N. (2005). Study of corrosiveness of acidic crude oil and it's fractions. Corrosion 2005, Nace International (ID 05568), Houston, USA.

Kane, R.D., Cayard, M.S. (2002). A comprehensive study on naphthenic acid corrosion. Corrosion 2002, Nace International (ID 02555), Denver, Colorado.

Kanukuntla, V., Qu, D., Nesic, S., Wolf, A. (2009). Experimental study of concurrent naphthenic acid and sulfidation. NACE International, Institute for Corrosion and Multiphase Technology Ohio University (Paper No. 2764), USA. https://www.ohio.edu/engineering/corrosion/research/upload/8214-10.pdf

Messer, B., Tarleton, B., Beaton, M., Phillips, T. (2004). New theory for naphthenic acid corrosivity of Athabasca oilsands crudes. Corrosion 2004, NACE Conference (ID 04634), New Orleans, USA.

Morantes, E., Bohórquez, E., Duarte, G., Pe-a, D.Y., Mateus, M. (2016). Análisis de depósitos formados sobre acero al carbono y acero 5Cr expuestos en fracciones de destilación atmosférica de la Refinería Barrancabermeja. ASCOR 2016, Cartagena de Indias, Colombia.

Ning, J., Zheng, Y., Brown, B., Young, D., Nesic, S. (2017). The role of iron sulfide polymorphism in localized H2S corrosion of mild steel. Corrosion 73 (2), 155-168. https://doi.org/10.5006/2030

Shoesmith, D.W. (1983). Formation, transformation and dissolution of phases formed on surfaces. Report, Atomic Energy of Canada Limited, Manitoba, Canada.

Tebbal, S., Shutt, H., Podlecki, R., Sudhakar, C. (2004). Analysis and corrosivity testing of eight crude oils. Corrosion 2004, NACE Conference (ID 04636), New Orleans, USA. PMCid:PMC497610

Yépez, O. (2005). Influence of different sulfur compounds on corrosion due to naphthenic acid. Fuel 84 (1), 97-104. https://doi.org/10.1016/j.fuel.2004.08.003

Published

How to Cite

Issue

Section

License

Copyright (c) 2017 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read here the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.