Effects of surface modification of thin wires of AISI 302 stainless steel by electrolytic plasma on its mechanical properties

DOI:

https://doi.org/10.3989/revmetalm.1152Keywords:

Electrolytic plasma technology (EPT), Contact glow discharge electrolysis (CGDE), Surface nanostructuration, Nanograins, Rupture strength, Plasma electrolytic oxidation (PEO)Abstract

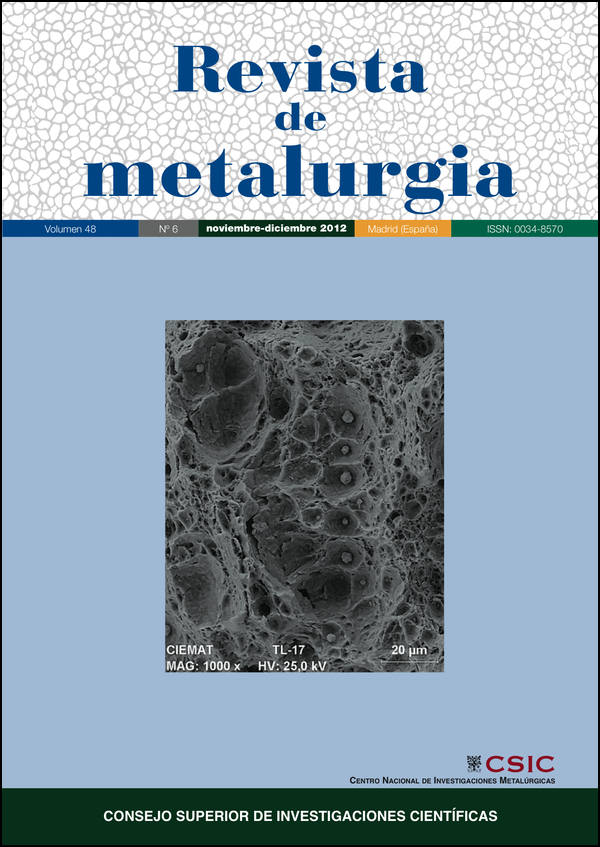

In this work different tests using electrolytic plasma (EP) on thin wires of stainless steel AISI 302 in an inert solution were performed. Tensile tests were carried out in order to measure changes in the mechanical strength of the samples; moreover, both the morphological and microstructural changes also were evaluated. It was found that after 10 s of the application of EP, the samples surface was uniformly covered by nodules-like and craters similar to those found in the melting and cooling periods of EP. The results show a significant surface grain refinement, leading to crystalline arrangements with sizes less than 200 nm and also an increase in the samples tensile strength of at least 57 % respect to steel base.

Downloads

References

[1] A. Azushima, R. Kopp, A. Korhonen, D.Y. Yang, F. Micari, G.D. Lahoti, P. Groche, J. Yanagimoto, N. Tsuji, A. Rosochowski y A. Yanagida, Manufacturing Technology 57 (2008) 716-735.

[2] L. Peraldo-Bicelli, B. Bozzini, C. Mele y L. D'Urzo, Int. J. Electrochem. Sci. 3 (2008) 356-408.

[3] X. Sauvage, A. Chbihi y X. Quelennec, J. Phys. Conference Series 240 (2010) 012003. http://dx.doi.org/10.1088/1742-6596/240/1/012003

[4] A. Rezaee, A. Najafizadeh, A. Kermanpur y M. Moallemi, Mater. Design. 32 (2011) 4.437-4.442. http://dx.doi.org/10.1016/j.matdes.2011.03.065

[5] M. Multigner, E. Frutos, J. L. González-Carrasco, J. A. Jiménez, P. Marín y J. Ibáñez, Mater. Sci. Eng. C-Bio S, 29 (2009) 1.357-1.360.

[6] X.Y. Wang y D.Y. Li, Electrochim. Acta 47 (2002) 3.939-3.947.

[7] X.Y. Wang y D.Y. Li, Wear 255 (2003) 836-845. http://dx.doi.org/10.1016/S0043-1648(03)00055-3

[8] L. Wang y D.Y. Li, Surf. Coat. Tech. 167 (2003) 188-196. http://dx.doi.org/10.1016/S0257-8972(02)00894-0

[9] H. Yun-wei, D. Bo, Z. Cheng, J. Yi-rning y L. Jin, J. Iron Steel Res. Int. 16 (2009) 8-72.

[10] X.H. Chen, J. Lu, L. Lu y K. Lu, Scripta Mater. 52 (2005) 1.039-1.044. http://dx.doi.org/10.1016/j.scriptamat.2004.09.008

[11] M. Ya, Y. Xing, F. Dai, K. Lu y J. Lu, Surf. Coat. Tech. 168 (2003) 148-155. http://dx.doi.org/10.1016/S0257-8972(03)00254-8

[12] C.T. Kwok, F.T. Cheng, H.C. Man y W.H. Ding, Mater. Lett. 60 (2006) 2.419-2.422. http://dx.doi.org/10.1016/j.matlet.2006.01.053

[13] S. Barriuso, M. Lieblich, M. Multigner, I. Etxeberria, A. Alberdi y J.L. González-Carrasco, Wear 270 (2011) 634-639. http://dx.doi.org/10.1016/j.wear.2011.01.024

[14] D. Bedorf y S.G. Mayr, Scripta Mater. 57 (2007) 853-856. http://dx.doi.org/10.1016/j.scriptamat.2007.06.059

[15] C. Cui, J. Hu, Y. Liu, K. Gao y Z. Guo, Appl. Surf. Sci. 254 (2008) 6.779-6.782.

[16] P. Gupta, G. Tenhundfeld, E.O. Daigle y D. Ryabkov, Surf. Coat. Tech. 201 (2007) 8.746-8.760. http://dx.doi.org/10.1016/j.surfcoat.2006.11.023

[17] H. H. Kellogg, J. Electrochem. Soc. 97 (1950) 133. http://dx.doi.org/10.1149/1.2777980

[18] A. Hickling y M. D. Ingram, Trans. Faraday Soc. 60 (1964) 783. http://dx.doi.org/10.1039/tf9646000783

[19] D.I. Slovetskii y S. D. Terent`ev, High Energ. Chem., 37 (2003) 310. http://dx.doi.org/10.1023/A:1025752813422

[20] C. W. M. P. Sillen, E. Barendrecht, L .J. J. Janssen y S.J. D. van Stralen, Int. J. Hydrog. Energ. 7 (1982) 577. http://dx.doi.org/10.1016/0360-3199(82)90038-6

[21] E.V. Parfenov, A. L.Yerokhin y A. Matthews, Surf. Coat. Tech. 201 (2007) 8.661-8.670.

[22] A.I. Maximov y A.V. Khlustova, Surf. Coat. Tech. 201 (2007) 8.782-8.788.

[23] E.I. Meletis, X. Nie, F.L. Wang y J.C. Jiang, Surf. Coat. Tech. 150 (2002) 246-256. http://dx.doi.org/10.1016/S0257-8972(01)01521-3

[24] T. Paulmier, J. M. Bell y P.M. Fredericks, Thin. Solid. Films. 515 (2007) 2.926-2.934.

[25] G. Sundararajan y L. Rama Krishna, Surf. Coat. Tech. 167 (2003) 269–277. http://dx.doi.org/10.1016/S0257-8972(02)00918-0

[26] J. Gao, A. Wang, Y. Li, Y. Fu, J. Wu, Youdi Wang y Yujing Wang, React. Funct. Polym. 68 (2008) 1.377-1.383. http://dx.doi.org/10.1016/j.reactfunctpolym.2008.06.018

[27] Q. Lu, J. Yu y J. Gao, J. Hazard Mater. B136 (2006) 526-531. http://dx.doi.org/10.1016/j.jhazmat.2005.11.001 PMid:16600477

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2012 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.