Effect of the polyacrylamide concentration on the quality of the copper deposit obtained by electrolytic refining

DOI:

https://doi.org/10.3989/revmetalm.1327Keywords:

Copper cathodes, Polyacrylamide, Grain size, Grain refiningAbstract

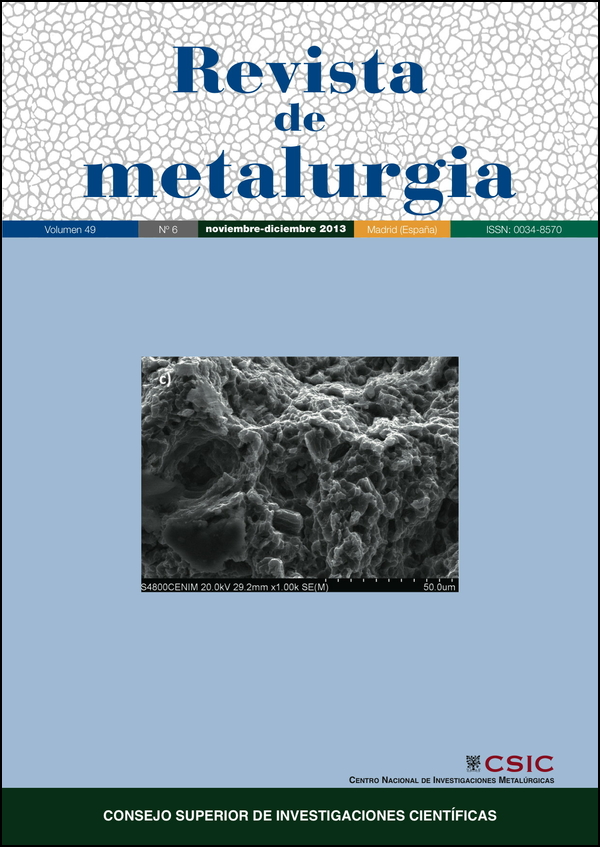

The effect of the additive non ionic polyacrylamide (PAM), was studied at the laboratory level, as refining crystalline grain in the copper electrorefining. Experiments were performed 24 h of electrolysis, using an electrolyte of copper sulphate acid, with 0.5 to 10 mgl-1 polyacrylamide at 55 °C and a current density of 260 Am-2. The effectiveness of these organic additives in copper electrorefining was determined by directly measuring the surface roughness of the copper deposit and contrasted with the results of other instrumental techniques (SEM and metallographic analysis). The results of the analysis SEM, metallographic analysis and measurement of the surface roughness of the copper deposit, show that to concentrations as low as 0.5 mgl-1 of this additive is manifested its property of tuner of grain. However, in the range of 7 to 10 mgl-1 of polyacrylamide, it reaches an optimum size of grain for the deposit of copper in the cathodes.

Downloads

References

[1] T.O' Keefe, Application of Polarisation Measurements in the Control of Metal Deposition, I.H. Warren (Ed.), Elsevier Science Publishers, Amesterdam, Holanda, 1984, pp. 15-31.

[2] S. Afifi, A. Elsayed y A. Elsherief, JOM 39 (1987) 38-41. http://dx.doi.org/10.1007/BF03259469

[3] Z. Mubarok, I. Filzwieser y P. Pashen, Proceeding/EMC 2005, Dresden, Alemania, 2005, pp. 109-122.

[4] R. Winand, Application of Polarisation Measurements in the Control of Metal Deposition, I. H. Warren (Ed.), Elsevier, Amsterdam, Holanda, 1984, pp. 47-83.

[5] P. Stanke, Procs. COPPER'99, Vol. III, Electrorefining & Electrowinning, Minerals, Metals, and Materials Society (Eds.), Phoenix, Arizona, EE.UU., 1999, pp. 643-651.

[6] M. Minakshi y M. Nicol, Proc. Hydrocopper 2009, E. Domic y J. Casas (Eds.), Antofagasta, Chile, 2009, pp. 382-391.

[7] L. Muresan, S. Varvara, G. Maurin y S. Dorneanu, Hydrometallurgy 2-3 (2000) 161-169. http://dx.doi.org/10.1016/S0304-386X(99)00063-8

[8] R. Yu, Q. Liu, G. Qiu, Z. Fang, J. Tan y P. Yang, T. Nonferr. Metal. Soc. 5 (2008) 1.280-1.284.

[9] G. Hope y G. Brown, Proc. 189th ECS Meeting, Symp., R. Ruoff y K. Kadish (Eds), Los Angeles, EE.UU., 1996, p. 1.097.

[10] S. Sandoval, C. Morales y C. Bernu, Proc. SME Annual Meeting and Exhibit 2010, Arizona, EE.UU., 2010, p. 540.

[11] Great Process Ltda. Regulador de grano DXG-F7, Ficha Técnica, www.gprocess.cl, Antofagasta, Chile.

[12] J. Vereecken y R. Winand, Surf. Technol. 4 (1976) 227-235. http://dx.doi.org/10.1016/0376-4583(76)90035-2

[13] C. Fabian, M. Ridd y M. Sheehan, Hydrometallurgy 1-2 (2007) 44-55. http://dx.doi.org/10.1016/j.hydromet.2006.11.002

[14] C. Fabian, M. Ridd y M. Sheehan, Hydrometallurgy 3-4 (2006) 256-263. http://dx.doi.org/10.1016/j.hydromet.2006.08.001

[15] H. Fischer, Plat. Surf. Finish. 56 (1969) 1.229-1.233.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2013 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read here the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.