Heat input effect on the microstructural transformation and mechanical properties in GTAW welds of a 409L ferritic stainless steel

DOI:

https://doi.org/10.3989/revmetalm.068Keywords:

409L ferritic stainless steel, GTAW, Heat input, Microhardness, Tensile properties, Weld thermal cyclesAbstract

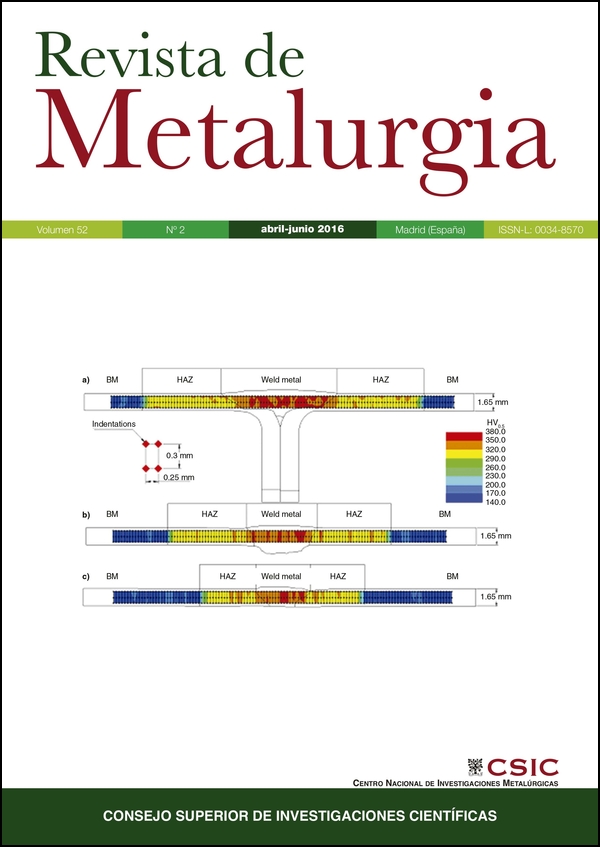

Welds without filler metal and welds using a conventional austenitic stainless steel filler metal (ER308L) were performed to join a ferritic stainless steel with Gas Tungsten Arc Welding process (GTAW). Welding parameters were adjusted to obtain three different heat input values. Microstructure reveals the presence of coarse ferritic matrix and martensite laths in the Heat Affected Zone (HAZ). Dilution between filler and base metal was correlated with the presence of austenite, martensite and ferrite in the weld metal. Weld thermal cycles were measured to correlate the microstructural transformation in the HAZ. Microhardness measurements (maps and profiles) allow to identify the different zones of the welded joints (weld metal, HAZ, and base metal). Comparing the base metal with the weld metal and the HAZ, a hardness increment (~172 HV0.5 to ~350 HV0.5 and ~310 HV0.5, respectively) was observed, which has been attributed to the martensite formation. Tensile strength of the welded joints without filler metal increased moderately with respect to base metal. In contrast, ductility was approximately 25% higher than base metal, which provided a toughness improvement of the welded joints.

Downloads

References

Ambriz, R.R., Chicot, D., Benseddiq, N., Mesmacque, G., de la Torre, S.D. (2011). Local mechanical properties of the 6061-T6 aluminium weld using micro-traction and instrumented indentation. Eur. J. Mech. - A/Solids. 30, 307-315. http://dx.doi.org/10.1016/j.euromechsol.2010.12.007

Amuda, M.O.H., Mridha, S. (2013). Grain refinement and hardness distribution in cryogenically cooled ferritic stainless steel welds. Mater. Design. 47, 365-371. http://dx.doi.org/10.1016/j.matdes.2012.12.008

ASTM E8 (2004). Standard test methods for tension testing of metallic materials.

Balmforth, M.C., Lippold, J.C. (1998). A preliminary ferriticmartensitic stainless steel constitution diagram. Weld. Res. Supplement. 77, 1s-7s.

Bayraktar, E., Moiron, J., Kaplan, D. (2006). Effect of welding conditions on the formability characteristics of thin sheet steels: Mechanical and metallurgical effects. J. Mater. Process. Tech. 175, 20-26. http://dx.doi.org/10.1016/j.jmatprotec.2005.04.007

Bayraktar, E., Katundi, D., Yilbas, B.S., Claeys, J. (2011). Toughness of welded stainless steels sheets for automotive industry. J. Achiev. Mater. Manuf. Eng. 44, 35-41.

Dowling, N.E. (2013). Mechanical behavior of materials, Engineering Methods for Deformation, Fracture and Fatigue, 4th Ed., Prentice Hall, Upper Saddle River, New Jersey.

Hakeem, A.M.O., Shahjahan, M. (2009). Microstructural features of AISI 430 Ferritic Stainless Steel (FSS) weld produced under varying process parameter. Int. J. Mech. Mat. Eng. 4, 160-166.

Katundi, D., Tosun-Bayraktar, A., Bayraktar, E., Toueix, D. (2010). Corrosion behaviour of the welded steel sheets used in automotive industry. J. Achiev. Mater. Manuf. Eng. 38, 146-153.

Lakshminarayanan, A.K., Shanmugam, K., Balasubramanian, V. (2009). Effect of welding processes on tensile, impact, hardness and microstructure of joints made of AISI 409M FSS base metal and AISI 308L ASS filler metals. Ironmak. Steelmak. 36, 75-80. http://dx.doi.org/10.1179/174328108X378224

Lakshminarayanan, A.K., Balasubramanian, V. (2012). Sensitization resistance of friction stir welded AISI 409 M grade ferritic stainless steel joints. Int. J. Adv. Manuf. Technol. 59, 961-967. http://dx.doi.org/10.1007/s00170-011-3552-7

Lippold, J.C., Kotecki, D.J. (2005). Welding Metallurgy and Weldability of Stainless Steels. 2nd Ed., Wiley, Hoboken, New Jersey. PMCid:PMC1287635

McGuire, M. (2008). Stainless Steel for Design Engineers. 1st. ASM International, Ohio, USA.

Mukherjee, M., Pal, T. (2012). Influence of mode of metal transfer on microstructure and mechanical properties of gas metal arc-welded modified ferritic stainless steel. Metall. Mater. Trans. A. 43, 1791-1808. http://dx.doi.org/10.1007/s11661-011-1069-1

Niekerk, C.J.V., Toit, M.D. (2011). Sensitization behaviour of 11-12% Cr AISI 409 stainless steel during low heat input welding. J. S. Afr. I. Min. Metall. 111, 243-256.

Okada, O., Nakata, K., Kasahara, S. (1999). Effects of thermal sensitization on radiation-induced segregation in type 304 stainless steel irradiated with He-ions. J. Nucl. Mater. 265, 232-239. http://dx.doi.org/10.1016/S0022-3115(98)00733-8

Pekkarinen, J., Kujanp.., V. (2010). The effects of laser welding parameters on the microstructure of ferritic and duplex stainless steels welds. Phys. Proc. 5, Part A, 517-523. http://dx.doi.org/10.1016/j.phpro.2010.08.175

Pham, T.-H., Kim, J.J., Kim, S.-E. (2014). Estimation of microstructural compositions in the weld zone of structural steel using nanoindentation. J. Constr. Steel Res. 99, 121-128. http://dx.doi.org/10.1016/j.jcsr.2014.04.011

Santos, B., Farias, C., Sobral, M. (2012). Spectral analysis of ultrasonic lamb waves applied to the study of the intermetallic phase presence on plates of AISI 430 ferritic stainless steel submitted to isothermal treatments, 18th World Conference on Nondestructive Testing, pp. 1-10.

Sathiya, P., Aravindan, S., Noorul Haq, A. (2007). Effect of friction welding parameters on mechanical and metallurgical properties of ferritic stainless steel. Int. J. Adv. Manuf. Technol. 31, 1076-1082. http://dx.doi.org/10.1007/s00170-005-0285-5

Shanmugam, K., Lakshminarayanan, A.K., Balasubramanian, V. (2009). Effect of weld metal properties on fatigue crack growth behaviour of gas tungsten arc welded AISI 409M grade ferritic stainless steel joints. Int. J. Pres. Ves. Pip. 86, 517-524. http://dx.doi.org/10.1016/j.ijpvp.2009.02.002

Villaret, V., Deschaux-Beaume, F., Bordreuil, C., Rouquette, S., Chovet, C. (2013). Influence of filler wire composition on weld microstructures of a 444 ferritic stainless steel grade. J. Mater. Process. Tech. 213, 1538-1547. http://dx.doi.org/10.1016/j.jmatprotec.2013.03.026

Published

How to Cite

Issue

Section

License

Copyright (c) 2016 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.