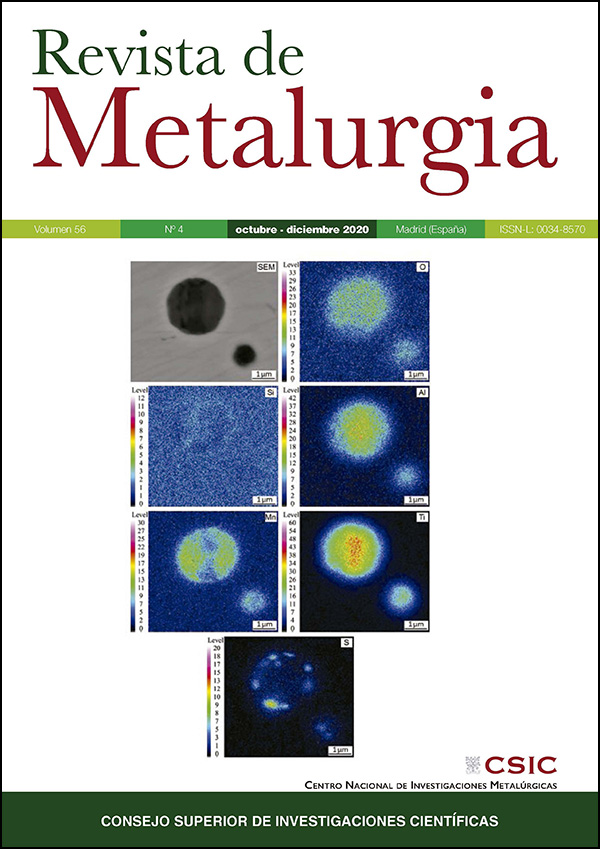

Synthesis and structural characterization of Fe based Ti+Ni3Al+Al2O3 reinforcement composite produced by mechanical alloying

DOI:

https://doi.org/10.3989/revmetalm.178Keywords:

Al2O3, Ball milling, Microhardness, Ni3Al, SinteringAbstract

The Fe-based Ti+Ni3Al+Al2O3 powder mixture is mechanically alloyed in a Spex ball mill. Composites with Fe-based Ti+Ni3Al+Al2O3 addition were produced at 1000 °C sintering temperature for 1 h sintering time. The metallurgical properties of these composites were examined by scanning electron microscopy (SEM), optical microscopy (OM), energy dispersive spectroscopy (EDS), X-ray diffraction (XRD) and microhardness analyses. The final products produced by mechanical alloying were nanocrystalline nickel-rich solid solution and the size of average crystallite was in the range of a few nanometres. Titanium content in the reinforcement increased microhardness values of composite. The produced composites included Fe3Al, TiAl, NiAl, Al3Ni2, Al2O3 and Fe3O phases.

Downloads

References

Akhtar, F. (2009). Synthesis, microstructure and mechanical properties of Al2O3 reinforced Ni3Al matrix composite. Mater. Sci. Eng. A. 499 (1-2), 415-420. https://doi.org/10.1016/j.msea.2008.09.005

Chérif, A., Rekik, H., Escoda, L., Sunol, J.J., Saurina, J., Khitouni, M., Makhlouf, T. (2016). Structural and thermal characterizations of the solid-state reaction between Ni, Al, and Ti powders during mechanical alloying. J. Therm. Anal. Calorim. 125 (2), 721-725. https://doi.org/10.1007/s10973-016-5355-4

Coreño Alonso, O., Cabañas-Moreno, J.G., Cruz-Rivera, J.J., Calderón, H.A., Umemoto, M., Tsuchiya, K., Quintana-Molina, S., Falcony, C. (2000). Characterization of NiAl intermetallic produced by mechanical alloying and consolidated by spark plasma sintering. Mater. Sci. Forum 343-346, 635-640. https://doi.org/10.4028/www.scientific.net/MSF.343-346.635

Eckert, J., Holzer, J.C., Krill, C.E., Johnson, W.L. (1992). Investigation of nanometer-sized FCC metals prepared by ball milling. Mater Sci. Forum 88-90, 505-512. https://doi.org/10.4028/www.scientific.net/MSF.88-90.505

Enayati, M.H., Sadeghian, Z., Salehi, M., Saidi, A. (2004). The effect of milling parameters on the synthesis of Ni3Al intermetallic compound by mechanical alloying. Mater. Sci. Eng. A. 375-377, 809-811. https://doi.org/10.1016/j.msea.2003.10.060

Forouzanmehr, N., Karimzadeh, F., Enayati, M.H. (2009). Synthesis and characterization of TiAl/α-Al2O3 nanocomposite by mechanical alloying. J. Alloys Compd. 478 (1-2), 257-259. https://doi.org/10.1016/j.jallcom.2008.12.047

Hwang, S.J., Nash, P., Dollar, M., Dymek, S. (1992). The production of intermetallics based on NiAl by mechanical alloying. Mater. Sci. Forum. 88-90, 611-618. https://doi.org/10.4028/www.scientific.net/MSF.88-90.611

Krivoroutchko, K., Kulik, T., Matyja, H., Portnoy, V.K., Fadeeva, V.I. (2000). Solid state reactions in Ni-Al-Ti-C system by mechanical alloying. J. Alloys Compd. 308 (1-2), 230-236. https://doi.org/10.1016/S0925-8388(00)00802-1

Li, J.L., Li, F., Hu, K. (2004). Preparation of Ni/Al2O3 nanocomposite powder by high-energy ball milling and subsequent heat treatment. J. Mater. Process. Tech. 147 (2), 236-240. https://doi.org/10.1016/j.jmatprotec.2003.12.022

Liu, E., Jia, J., Bai, Y., Wang, W., Gao, Y. (2014). Study on preparation and mechanical property of nanocrystalline NiAl intermetallic. Mater. Des. 53, 596-601. https://doi.org/10.1016/j.matdes.2013.07.052

Mao, S.X., McMinn, N.A., Wu, N.Q. (2003). Processing and mechanical behaviour of TiAl/NiAl intermetallic composites produced by cryogenic mechanical alloying. Mater. Sci. Eng. A. 363 (1-2), 275-289. https://doi.org/10.1016/S0921-5093(03)00652-X

Moshksar, M.M., Mirzaee, M. (2004). Formation of NiAl intermetallic by gradual and explosive exothermic reaction mechanism during ball milling. Intermetallics 12 (12), 1361-1366. https://doi.org/10.1016/j.intermet.2004.03.018

Pippan, R., Wetscher, F., Hafok, M., Vorhauer, A., Sabirov, I. (2006). The limits of refinement by severe plastic deformation. Adv. Eng. Mater. 8 (11), 1046-1056. https://doi.org/10.1002/adem.200600133

Sheu, H.H., Hsiung, L.C., Sheu, J.R. (2009). Synthesis of multiphase intermetallic compounds by mechanical alloying in Ni-Al-Ti system. J. Alloys Compd. 469 (1-2), 483-487. https://doi.org/10.1016/j.jallcom.2008.02.019

Sheng, L., Zhang, W., Guo, J., Yang, F., Liang, Y., Ye, H. (2010). Effect of au addition on the microstructure and mechanical properties of NiAl intermetallic compound. Intermetallics 18 (4), 740-744. https://doi.org/10.1016/j.intermet.2009.10.015

Song, J., Hu, W., Gottstein, G. (2011). Long term stability and mechanical properties of Al2O3-NiAl composites reinforced with partially fragmented long fibers. Mater. Sci. Eng. A. 528 (25-26), 7790-7800. https://doi.org/10.1016/j.msea.2011.07.002

Suryanarayana, C. (2001). Mechanical alloying and milling. Prog. Mater. Sci. 46 (1-2), 1-184. https://doi.org/10.1016/S0079-6425(99)00010-9

Wieczorek-Ciurowa, K., Gamrat, K. (2005). NiAl/Ni3Al-Al2O3 composite formation by reactive ball milling. J. Therm. Anal. Calorim. 82, 719-724. https://doi.org/10.1007/s10973-005-0955-4

Zelaya, E., Esquivel, M.R., Schryvers, D. (2013). Evolution of the phase stability of Ni-Al under low energy ball milling. Adv. Powder Technol. 24 (6), 1063-1069. https://doi.org/10.1016/j.apt.2013.03.008

Published

How to Cite

Issue

Section

License

Copyright (c) 2020 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.