Characterization of iron nugget produced from iron ore concentrate in a microwave oven using a biomass-based reductant

DOI:

https://doi.org/10.3989/revmetalm.250Keywords:

Biomass, Carbonized tea plant waste, Composite pellet, Iron nugget, Magnetite, Microwave reductionAbstract

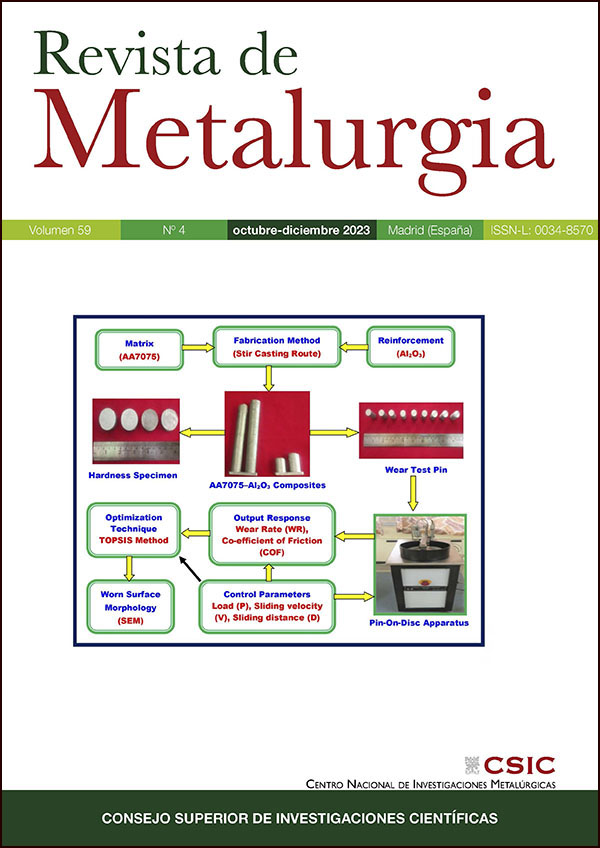

This study is concerned with the characterization of iron nuggets obtained from the reduction of an iron oxide concentrate in a microwave oven using a biomass-based reducing agent. In the experiments, the concentrate of iron ore consisting of hematite and magnetite minerals supplied from Elazig region and containing 67.29% Fe after enrichment, and as a reducing agent, tea plant wastes containing 94.68% C and 0.03% S after carbonization was used. Carbon required for the reduction of iron oxides to iron was stoichiometrically added to the concentrate with a grain size of -45 µm after its basicity ratio was adjusted. The composite pellets produced after the addition of reducing agent and flux (CaO) were subjected to reduction in a household microwave oven at different times. After the process, optimum (Fe3O4+Fe2O3)/C=1/4, basicity ratio (CaO+MgO)/(SiO2+Al2O3) =1.2 results were obtained. It was seen that the metallic part contained 96.6% Fe, 2.4% C after being separated from the slag and that the metallic phase was separated from the slag very easily. As a result of the microstructure investigations, it was found that the product obtained had similar properties to white cast iron properties.

Downloads

References

Agrawal, B.B., Prasad, K.K., Sarkar, S.B., Ray, H.S. (2000). Cold bonded ore-coal composite pellets for sponge ironmaking Part 1 Laboratory Scale Development. Ironmak. Steelmak. 27 (6), 421-425.

https://doi.org/10.1179/030192300677723

Arancı, E.Ö., Bostancı, B., Benkli, Y.E., Boyrazlı, M., Çizmecioğlu, Z. (2017). The Effect of Using Potato Starch as a Binder on the Pellet Strength of Cold-Hardened Pellets. IATS'17, 3622220.

Benkli, Y.E. (2008). Soğukta Sertleşen Kompozit Peletlerin Yarı Ergitme Şartlarında İndirgenmesinin Araştırılması. PhD Thesis, YTU Institute of Science and Technology, Istanbul. http://dspace.yildiz.edu.tr/xmlui/handle/1/1939.

Benkli, Y.E., Boyrazli, M., Senoz, G.M.L., Cizmecioglu, Z. (2018). Investigation of reduction of magnetite based carbon composite pellets under semi-fusion conditions. Physicochem. Probl. Miner. Process. 54 (3), 621-628.

Bostancı, B., Cihangiroğlu, E., Boyrazlı, M., Arancı, E.Ö. (2017). The Effect of CMC Addition on Briquet Strength in Production of Cold Bonded Briquette with Iron Based Powders. IATS'17, 3622437.

Boyrazlı, M., Arancı Öztürk E., Benkli, Y.E. (2017). The Effect of the Grinding Time on the Mechanical Activation of MnO2 Ore and Tea Plant Waste Carbonization Product. J. Phys. Sci. Appl. 7 (4) 59-65. .

https://doi.org/10.17265/2159-5348/2017.04.007

Clark, D.E., Sutton, W.H. (1996). Microwave Processing of Materials. Annu. Rev. Mater. Sci. 26, 299-330.

https://doi.org/10.1146/annurev.ms.26.080196.001503

Çizmecioğlu, Z., Sarıdede, M.N. (2005). Türkiye İçin Uygun Sünger Demir Üretim Teknolojisinin Araştırılması. Project prepared by Erdemir Maden for YTU, Istanbul.

Demir, I. (2006). An investigation on the production of construction brick with processed waste tea. Build. Environ. 41 (9), 1274-1278.

https://doi.org/10.1016/j.buildenv.2005.05.004

Doru, M., Stefanescu (1990). ASM Handbook, Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International, Volume 1, pp. 3-11.

https://doi.org/10.31399/asm.hb.v01.a0009206

Grote, K.H., Antonsson, E. (2008). Handbook of Mechanical Engineering. Springer, pp. 531.

https://doi.org/10.1007/978-3-540-30738-9

Güler, Ö., Boyrazlı, M., Başgöz, Ö., Bostancı, B. (2017). The synthesis of carbon nanostructures from tea plant wastes. Can. Metall. Q. 56 (3), 349-359.

https://doi.org/10.1080/00084433.2017.1345467

Güler, C., Pekşen, A. (2003). Using tea waste as a new casing material in mushroom (Agaricus bisporus (L.) sing.) cultivation. Bioresource Technology 88 (2), 153-156.

https://doi.org/10.1016/S0960-8524(02)00279-1

PMid:12576009

Gürten, İI (2008). Production of Adsorbent from Tea Waste and Investigation of Adsorption Properties of Produced Adsorbent. Master Thesis, Ankara University

Kawatra, S.K., Anameric, B., Eisele, T.C. (2005). Single-Step Ironmaking from Ore to Improve Energy Efficiency. Final Technical Report, DOE Award Number: DE-FG26-03NT41930, pp. 70. https://www.osti.gov/servlets/purl/887121.

https://doi.org/10.2172/887121

PMid:35769989

Kıkuchı, S., Ito, S., Kobayashı, I., Tsuge, O., Tokuda, K. (2010). ITmk3 Process. Kobelco Technology Review N° 29, pp. 77-84.

Orhan, Y.O., Büyükgüngör, H. (1993). The removal of heavy-metals by using agricultural wastes. Water Sci. Technol. 28 (2), 247-255. https://www.researchgate.net/publication/279894925_The_Removal_of_Heavy_Metals_by_Using_Agricultural_Waste.

https://doi.org/10.2166/wst.1993.0114

Peacey, J.G., Davenport, W.G. (1979). The Blast Furnace Theory and Practice. Pergamon Press, 1st Edition, pp. 7.

https://doi.org/10.1016/B978-0-08-023218-8.50007-8

Smith, W.F. (1993). Structure and Properties of Engineering Alloys. McGraw-Hill Materials Science and Engineering Series, 2nd Edition, 1-41, 82, 336.

Standish, N., Worner, H. (1990). Microwave application in the reduction of metal oxides with carbon. JMPEE 25 (3), 177-180.

https://doi.org/10.1080/08327823.1990.11688126

Sun, X., Hwang, J.Y., Huang, X., Li, B., Shi, S. (2005). Effects of Microwave on Molten Metals with Low Melting Temperatures. JMMCE 4 (2), 107-112.

https://doi.org/10.4236/jmmce.2005.42010

Tiftik, B.E. (2006). Çay Fabrikası Atığının Pirolizi ve Piroliz Ürünlerinin İncelenmesi. Master Thesis, Ankara University..

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read here the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.