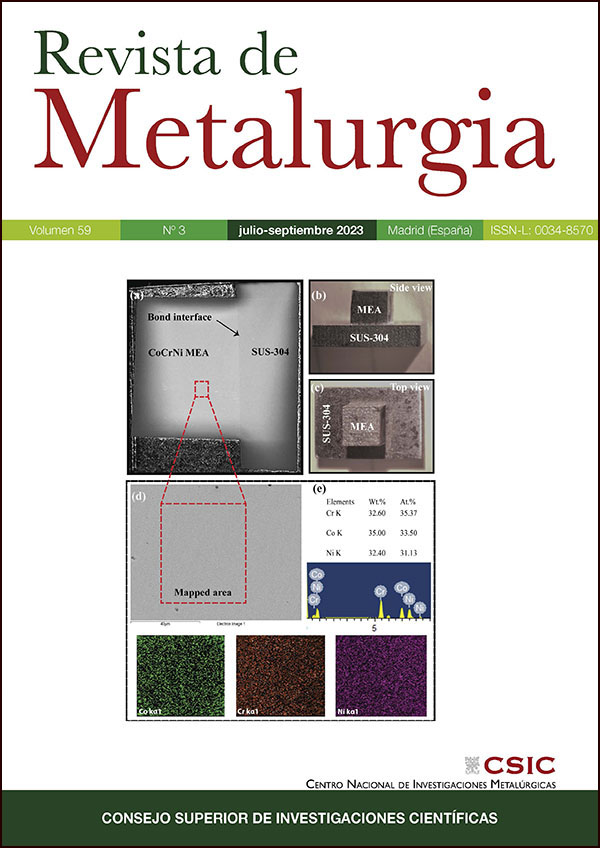

Evaluation of nano mechanical properties and corrosion behavior of diffusion welded CoCrNi medium-entropy alloy (MEA) and SUS 304 stainless steel joints

DOI:

https://doi.org/10.3989/revmetalm.244Keywords:

Electrochemical Impedance Spectroscopy (EIS), HCl environment, Medium Entropy Alloy (MEA), Nano-indentation, Potentiodynamic Polarization (PD), SUS 304 Stainless SteelAbstract

The study mainly focused on examining nanomechanical properties and corrosion behavior of the weld interface formed by diffusion welding of CoCrNi MEA and SUS 304 stainless steel. Three different bonding temperatures (i.e. 950 °C, 1000 °C, and 1050 °C) were utilized in producing diffusion welded joints. The influence of bonding temperatures on nanomechanical properties of the weld interface was characterized through Nanoindentation tests under various loads (i.e. 20 mN to 100 mN). Additionally, electrochemical properties of the weld interface were also examined using a 0.5 M HCl solution. Results clinched that with the increase of bonding temperature significant suppression in carbide formation occurred along with the weld interface. This instigated a reduction in nano hardness and elastic moduli which resulted in maximum elastic recovery along with the weld interface. The indentation size effect was also evident below 40 mN load after which nano hardness became stable while elastic moduli remained impervious to the change of indentation load. Furthermore, based upon electrochemical properties (i.e. Icorr, Ep, and Rp) samples welded at 1000 °C bonding temperature offered excellent corrosion resistance under 0.5M HCl environment.

Downloads

References

Adomako, N.K., Kim, J.H., Hyun, Y.T. (2018). High-temperature oxidation behaviour of low-entropy alloy to medium- and high-entropy alloys. J. Therm. Anal. Calorim. 133 (1), 13-26. https://doi.org/10.1007/s10973-018-6963-y

Alhafez, I.A., Ruestes, C.J., Zhao, S., Minor, A.M., Urbassek, H.M. (2021). Dislocation structures below a nano-indent of the CoCrNi medium-entropy alloy. Mater. Lett. 283, 128821. https://doi.org/10.1016/j.matlet.2020.128821

An, X.L., Zhao, H., Chu, C.L., Dai, T., Lu, T., Huang, Z.H., Guo, C., Chu, P.K. (2019). Hall-Petch relationship and corrosion behavior of cold-rolled CoNiFe medium entropy alloy. J. Alloys Compd. 807, 151698. https://doi.org/10.1016/j.jallcom.2019.151698

Behpour, M., Ghoreishi, S.M., Soltani, N., Salavati-Niasari, M. (2009). The inhibitive effect of some bis-N, S-bidentate Schiff bases on corrosion behaviour of 304 stainless steel in hydrochloric acid solution. Corros. Sci. 51 (5), 1073-1082. https://doi.org/10.1016/j.corsci.2009.02.011

Bridges, D., Zhang, S., Lang, S., Gao, M., Yu, Z., Feng, Z., Hu, A. (2018). Laser brazing of a nickel-based superalloy using a Ni-Mn-Fe-Co-Cu high entropy alloy filler metal. Mater. Letters 215, 11-14. https://doi.org/10.1016/j.matlet.2017.12.003

Cantor, B., Chang, I.T., Knight, P., Vincent, A.J. (2004). Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 375-377, 213-218. https://doi.org/10.1016/j.msea.2003.10.257

Chai, L., Tassou, S.A. (2020). A review of printed circuit heat exchangers for helium and supercritical CO2 Brayton cycles. Therm. Sci. Eng. Prog. 18, 100143. https://doi.org/10.1016/j.tsep.2020.100543

Clark, D.E., Mizia, R.E., Piyush, S. (2012a). Diffusion Welding of Alloys for Molten Salt Service - Status Report. USA, pp. 1-19. https://www.osti.gov/biblio/1070108.

Clark, D.E., Mizia, R.E., Glazoff, M.V., Patterson, M.W. (2012b). Diffusion Welding of Compact Heat Exchangers for Nuclear Applications. Idaho National Laboratory, Idaho Falls, Idaho, USA, pp. 1-28.

Du, Y., Li, Z., Xiong, J., Chen, Y., Li, S., Li, J., Dong, J. (2021). Diffusion Bonding of FGH 98 and CoCrNi-Based Medium-Entropy Alloy: Microstructure Evolution and Mechanical Tests. Crystals 11 (10), 1158. https://doi.org/10.3390/cryst11101158

Fang, J.Y.C., Liu, W.H., Luan, J.H., Jiao, Z.B. (2021). Phase Stability and Precipitation in L12-Strengthened CoCrNi Medium-Entropy Alloys at Intermediate Temperatures. J. Phase Equilib. Diffus. 42 (5), 781-793. https://doi.org/10.1007/s11669-021-00919-4

Gan, B., Wheeler, J.M., Bi, Z., Liu, L., Zhang, J., Fu, H. (2019). Superb cryogenic strength of equiatomic CrCoNi derived from gradient hierarchical microstructure. J. Mater. Sci. Technol. 35 (6), 957-961. https://doi.org/10.1016/j.jmst.2018.12.002

Gao, H., He, G., Li, Q., Li, Y., Hu, W., Zhou, S., Liu, F., Yi, J., Zhang, Y., Cai, Z., Ogata, S., Qiao, L., Gao, L. (2023). Diffusion bonding of high entropy alloy and stainless steel at a relative lower temperature via surface nano-crystallization treatment. J. Mater. Res. Technol. 24, 475-487. https://doi.org/10.1016/j.jmrt.2023.03.026

Gludovatz, B., Hohenwarter, A., Thurston, K.V., Bei, H., Wu, Z., George, E.P., Ritchie, R.O. (2016). Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 7 (1), 10602. https://doi.org/10.1038/ncomms10602 PMid:26830651 PMCid:PMC4740901

Hua, D., Xia, Q., Wang, W., Zhou, Q., Li, S., Qian, D., Shi, J., Wang, H. (2021). Atomistic insights into the deformation mechanism of a CoCrNi medium entropy alloy under nanoindentation. Int. J. Plas. 142, 102997. https://doi.org/10.1016/j.ijplas.2021.102997

Hussainova, I., Jasiuk, I., Du, X., Cabassa, D. Pirso, J. (2008). Mechanical properties of chromium carbide based cermets at micro - level. In Advances in powder metallurgy & particulate materials. PowderMet 2008, Washington, DC, USA.

Kashaev, N., Ventzke, V., Stepanov, N., Shaysultanov, D., Sanin, V., Zherebtsov, S. (2018). Laser beam welding of a CoCrFeNiMn-type high entropy alloy produced by self-propagating high-temperature synthesis. Intermetallics 96, 63-71. https://doi.org/10.1016/j.intermet.2018.02.014

Kleykamp, H. (2001). Thermodynamic studies on chromium carbides by the electromotive force (emf) method. J. Alloys Compd. 321 (1), 138-145. https://doi.org/10.1016/S0925-8388(01)01012-X

Kumar, N., Fusco, M., Komarasamy, M., Mishra, R.S., Bourham, M., Murty, K.L. (2017). Understanding effect of 3.5 wt.% NaCl on the corrosion of Al0.1CoCrFeNi high-entropy alloy. J. Nucl. Mater. 495, 154-163. https://doi.org/10.1016/j.jnucmat.2017.08.015

Ladani, L., Harvey, E., Choudhury, S.F., Taylor, C.R. (2013). Effect of Varying Test Parameters on Elastic-plastic Properties Extracted by Nanoindentation Tests. Exp. Mech. 53 (8), 1299-1309. https://doi.org/10.1007/s11340-013-9732-7

Laplanche, G., Kostka, A., Reinhart, C., Hunfeld, J., Eggeler, G., George, E.P. (2017). Reasons for the superior mechanical properties of medium-entropy CrCoNi compared to high-entropy CrMnFeCoNi. Acta Mater. 128, 292-303. https://doi.org/10.1016/j.actamat.2017.02.036

Li, J., Fang, Q., Liu, B., Liu, Y.W., Liu, Y. (2016). Atomic-scale analysis of nanoindentation behavior of high-entropy alloy. J. Micromech. Mol. Phys. 1 (1), 1650001. https://doi.org/10.1142/S2424913016500016

Li, S., Li, J., Shi, J., Du, Y., Peng, Y., Jin, F., Xiong, J., Zhang, F. (2021a). Microstructure and mechanical properties of the brazed region in the AlCoCrFeNi high-entropy alloy and FGH98 superalloy joint. Mater. Sci. Eng. A 804, 140714. https://doi.org/10.1016/j.msea.2020.140714

Li, S., Sun, X., Du, Y., Peng, Y., Chen, Y., Li, Z., Xiong, J., Li, J. (2021b). Microstructure and Mechanical Properties of Diffusion-Bonded CoCrNi-Based Medium-Entropy Alloy to DD5 Single-Crystal Superalloy Joint. Crystals 11 (9), 1127. https://doi.org/10.3390/cryst11091127

Li, P., Sun, H.-t., Li, C., Wu, B.-s., Yang, J., Jiang, Y., Dong, H.-g (2023). A novel strengthening strategy for diffusion bonded joint of AlCoCrFeNi2.1 eutectic high entropy alloy to 304 stainless steel. Trans. Nonferrous Met. Soc. China 33 (7), 2121-2135. https://doi.org/10.1016/S1003-6326(23)66248-X

Lu, C., Yang, T.-N., Jin, K., Velisa, G., Xiu, P., Peng, Q., Gao, F., Zhang, Y., Bei, H., Weber, W.J., Wang, L. (2019). Irradiation effects of medium-entropy alloy NiCoCr with and without pre-indentation. J. Nucl. Mater. 524, 60-66. https://doi.org/10.1016/j.jnucmat.2019.06.020

Luo, H., Li, Z., Mingers, A.M., Raabe, D. (2018). Corrosion behavior of an equiatomic CoCrFeMnNi high-entropy alloy compared with 304 stainless steel in sulfuric acid solution. Corros. Sci. 134, 131-139. https://doi.org/10.1016/j.corsci.2018.02.031

Machnikova, E., Whitmire, K.H., Hackerman, N. (2008). Corrosion inhibition of carbon steel in hydrochloric acid by furan derivatives. Electrochim. Acta 53 (20), 6024-6032. https://doi.org/10.1016/j.electacta.2008.03.021

Maier-Kiener, V., Schuh, B., George, E.P., Clemens, H., Hohenwarter, A. (2017). Nanoindentation testing as a powerful screening tool for assessing phase stability of nanocrystalline high-entropy alloys. Mater. Des. 115, 479-485. https://doi.org/10.1016/j.matdes.2016.11.055

McCafferty, E. (2010). Introduction to corrosion science. Springer Science & Business Media. https://doi.org/10.1007/978-1-4419-0455-3

Moravcik, I., Peighambardoust, N.S., Motallebzadeh, A., Moravcikova-Gouvea, L., Liu, C., Prabhakar, J.M., Dlouhy, I., Li, Z. (2021). Interstitial nitrogen enhances corrosion resistance of an equiatomic CoCrNi medium-entropy alloy in sulfuric acid solution. Materials Characterization 172, 110869. https://doi.org/10.1016/j.matchar.2020.110869

Muhammad Samiuddin., Jinglong, L., Siddiqui, M.A., Jiangtao, X., Ling, R. (2021). Electrochemical Corrosion Behavior of CoCrNi Medium Entropy Alloy and SUS-304 Stainless Steel Diffusion Welded Joints at Various Bonding Temperatures. Phys. Metals Metallogr. 122 (14), 1561-1571. https://doi.org/10.1134/S0031918X21140234

Muthupandi, G., Lim, K.R., Na, Y.-S., Park, J., Lee, D., Kim, H., Park, S., Choi, Y.S. (2017). Pile-up and sink-in nanoindentation behaviors in AlCoCrFeNi multi-phase high entropy alloy. Mater. Sci. Eng. A 696, 146-154. https://doi.org/10.1016/j.msea.2017.04.045

Oliver, W.C., Pharr, G.M. (2004). Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 19 (1), 3-20. https://doi.org/10.1557/jmr.2004.19.1.3

Peng, Y., Li, J., Shi, J., Li, S., Xiong, J. (2021). Microstructure and mechanical properties of diffusion bonded joints of high-entropy alloy Al5(HfNbTiZr)95 and TC4 titanium alloy. J. Mater. Res. Technol. 11, 1741-1752. https://doi.org/10.1016/j.jmrt.2021.02.003

Sadeghilaridjani, M., Mukherjee, S. (2020). High-Temperature Nano-Indentation Creep Behavior of Multi-Principal Element Alloys under Static and Dynamic Loads. Metals 10 (2), 250. https://doi.org/10.3390/met10020250

Sah, I., Hwang, J.-B., Kim, W.-G., Kim, E.-S., Kim, M.-H. (2020). High-temperature mechanical behaviors of diffusion-welded Alloy 617. Nuclear Engineering and Design 364, 1106-1121. https://doi.org/10.1016/j.nucengdes.2020.110617

Samiuddin, M., Li, J., Chandio, A.D., Muzamil, M., Siddiqui, S.U., Xiong, J. (2021). Diffusion welding of CoCrNi medium entropy alloy (MEA) and SUS 304 stainless steel at different bonding temperatures. Weld. World 65 (11), 2193-2206. https://doi.org/10.1007/s40194-021-01165-5

Sathiyamoorthi, P., Bae, J.W., Asghari-Rad, P., Park, J.M., Kim, J.G., Kim, H.S. (2018). Effect of Annealing on Microstructure and Tensile Behavior of CoCrNi Medium Entropy Alloy Processed by High-Pressure Torsion. Entropy 20 (11), 849. https://doi.org/10.3390/e20110849 PMid:33266573 PMCid:PMC7512411

Shang, X., Wang, Z., He, F., Wang, J., Li, J., Yu, J.K. (2017). The intrinsic mechanism of corrosion resistance for FCC high entropy alloys. Sci. China Technol. Sci. 61 (2), 189-196. https://doi.org/10.1007/s11431-017-9114-1

Shuang, S., Lu, S., Zhang, B., Bao, C., Kan, Q., Kang, G., Zhang, X. (2021). Effects of high entropy and twin boundary on the nanoindentation of CoCrNiFeMn high-entropy alloy: A molecular dynamics study. Comput. Mater. Sci. 195, 110495. https://doi.org/10.1016/j.commatsci.2021.110495

Silva, D.D.S., Lima, L., Araujo, A.J.M., Silva, V.D., Raimundo, R.A., Damasceno, I. Z., Simoes, T.A., Gomes, R.M. (2020). The Effect of Microstructural Changes on Mechanical and Electrochemical Corrosion Properties of Duplex Stainless Steel Aged for Short Periods. Materials 13 (23), 5511. https://doi.org/10.3390/ma13235511 PMid:33287152 PMCid:PMC7730082

Silva, D.D.S., Simões, T.A., Macedo, D.A., Bueno, A.H.S., Torres, S.M., Gomes, R.M. (2021). Microstructural influence of sigma phase on pitting corrosion behavior of duplex stainless steel/NaCl electrolyte couple. Mater. Chem. Phys. 259, 124056. https://doi.org/10.1016/j.matchemphys.2020.124056

Sorour, A.A., Farooq, M., Mekki, A., Kumar, A.M. (2021). Corrosion of a Spark Plasma Sintered Fe-Cr-Mo-BC Alloy in Hydrochloric Acid. Metallogr. Microstruct. Anal. 10 (3), 291-301. https://doi.org/10.1007/s13632-021-00739-5

Southall, D., Pierres, R. Le, Dewson, S.J. (2008). Design considerations for compact heat exchangers. United States, American Nuclear Society - ANS.

Sun, H., Hashimoto, N., Oka, H. (2023). Vacuum diffusion bonding between equiatomic CoCrNi-based concentrated solid solution alloys system and 316 stainless steel by spark plasma sintering. Mater. Sci. Eng. A 879, 145297. https://doi.org/10.1016/j.msea.2023.145297

Voyiadjis, G.Z., Yaghoobi, M. (2017). Review of Nanoindentation Size Effect: Experiments and Atomistic Simulation. Crystals 7 (10), 321. https://doi.org/10.3390/cryst7100321

Wallinder, D., Pan, J., Leygraf, C., Delblanc-Bauer, A. (1998). EIS and XPS study of surface modification of 316LVM stainless steel after passivation. Corros. Sci. 41 (2), 275-289. https://doi.org/10.1016/S0010-938X(98)00122-X

Wang, J., Yang, H., Ruan, J., Wang, Y., Ji, S. (2019). Microstructure and properties of CoCrNi medium-entropy alloy produced by gas atomization and spark plasma sintering. J. Mater. Res. 34 (12), 2126-2136. https://doi.org/10.1557/jmr.2019.96

Wu, Z., Bei, H., Otto, F., Pharr, G.M., George, E.P. (2014). Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys. Intermetallics 46, 131-140. https://doi.org/10.1016/j.intermet.2013.10.024

Yeh, J.W., Chen, S.K., Lin, S.J., Gan, J.I., Chin, T.S., Shun, T.T., Tsau, C.H., Chang, S.Y. (2004). Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv. Eng. Mater. 6 (5), 299-303. https://doi.org/10.1002/adem.200300567

Yeh, J.-W. (2013). Alloy design strategies and future trends in high-entropy alloys. JOM 65 (12), 1759-1771. https://doi.org/10.1007/s11837-013-0761-6

Yi, H., Bi, M., Yang, K., Zhang, B. (2020). Significant Improvement the Mechanical Properties of CoCrNi Alloy by Tailoring a Dual FCC-Phase Structure. Materials 13 (21), 4909. https://doi.org/10.3390/ma13214909 PMid:33142889 PMCid:PMC7663278

Zhu, M., He, F., Yuan, Y., Guo, S., Wei, G. (2021). A comparative study on the corrosion behavior of CoCrNi medium-entropy alloy and 316L stainless steel in simulated marine environment. Intermetallics 139, 107370. https://doi.org/10.1016/j.intermet.2021.107370

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.