Influence of the chemical composition of different steel scraps on the mechanical properties of ductile iron

DOI:

https://doi.org/10.3989/revmetalm.1044Keywords:

Raw materials, Chemical composition, Ductile iron, Mechanical properties, Matrix structureAbstract

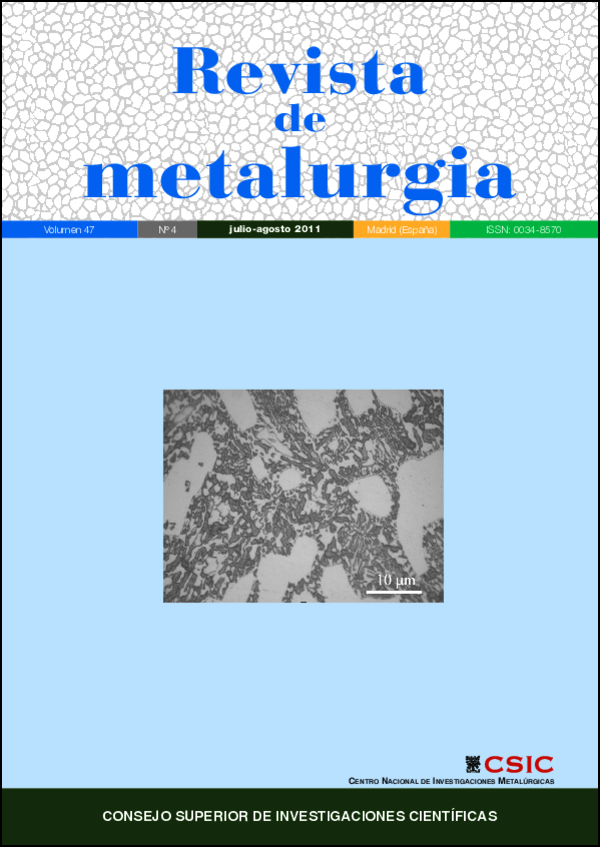

Different commercial steel scraps have been selected so as to analyse the outcome of their use as raw materials and to evaluate their applicability in the production of ductile iron castings. These selected steels show an important chemical variability mainly depending on their origin and on their previous utilisation. According to that, alloying elements added through these materials have been determined and their effects on the structural characteristics and the mechanical properties of test-castings with different shape and size have been studied. The most important element added is manganese, which is included in all the selected scraps with contents higher than 0.2 %. Other elements are: copper, chromium, tin, titanium and vanadium. All of them are known as pearlite promoters apart from titanium and vanadium. Therefore, these elements can be used for manufacturing casting containing pearlitic and/or mixed ferritic and pearlitic structures. No carbides were found in all the test castings.

Downloads

References

[1] M. Naito, Nippon Steel Tech. Rep. Report. 94 (2006) 2-15.

[2] N. G. Bliss, AFS Trans. 105 (1997) 27-30.

[3] J. Aylen y K. Albertson, Ironmak Steelmak 33 (2006) 203-212. http://dx.doi.org/10.1179/174328106X101538

[4] G.F. Geiger, W. Bauer, B.J. McKay Y P. Schumacher, Mat. Sci. Eng. A413-414 (2005) 339-345.

[5] R. A. Harding y M. L. H. Wise, AFS Trans. 108 (2000) 129-136.

[6] P. Dupin y J. M. Schissler, AFS Trans. 92 (1984) 355-360.

[7] S. Parent-Simonin, Fonderie, (1987) 45-51.

[8] D. Venugopalan y A. Alagarsamy, AFS Trans. 98 (1990) 395-400.

[9] J. Sertucha, P. Larrañaga, J. Lacaze y M. Insausti, Int. J. Metalcast. (2010) 51-58.

[10] J. Lacaze, A. Boudot, V. Gerval, D. Oquab y H. Santos, Metall. Mater. Trans. A, 28A (1997) 2.015-2.025.

[11] R. Boeri y F. Weinberg, AFS. Trans. 97 (1989) 179-184.

[12] C. Selig y J. Lacaze, Metall. Mater. Trans. B, 31B (2000) 827-836. http://dx.doi.org/10.1007/s11663-000-0119-7

[13] G.M. Goodrich, T.G. Oakwood y R.B.Gundlach, Modern Casting, (2006) 42-44.

[14] A. Loizaga, J. Sertucha y R. Suárez, An. Quím. 104 (2008) 111-119.

[15] J. Lastovica, Proc. Inter. PhD Foundry Conf. Brno, República Checa, 2009, pp 1-8.

[16] J. R. Brown, Foseco Ferrous Foundryman´s Handbook Ed. Hardcover (2000) 124-125.

[17] A. Javaid y E. Essadiqi, Final report on scrap management, sorting and classification of steel (2003) Government of Canada, Report No. 2003-23(CF).

[18] P. Larrañaga, J. Sertucha y R. Suárez, Rev. Metal Madrid 42 (2006) 244-255.

[19] F. Lietaert, Giessereiforschung 49 (1997) 106-122.

[20] E. N. Pan, M. S. Lou y C. R. Loper, AFS Trans. 95 (1987) 819-840.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2011 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read here the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.