Phase transformations in Zn-22%Al-2%Cu and Zn-22%Al-2%Cu-X (X = 1, 2 and 3%Ag) alloys during aging treatments

DOI:

https://doi.org/10.3989/revmetalm.026Keywords:

Ag addition, Four phases reaction, Phase transformations, Precipitation, Zn-Al-Cu alloysAbstract

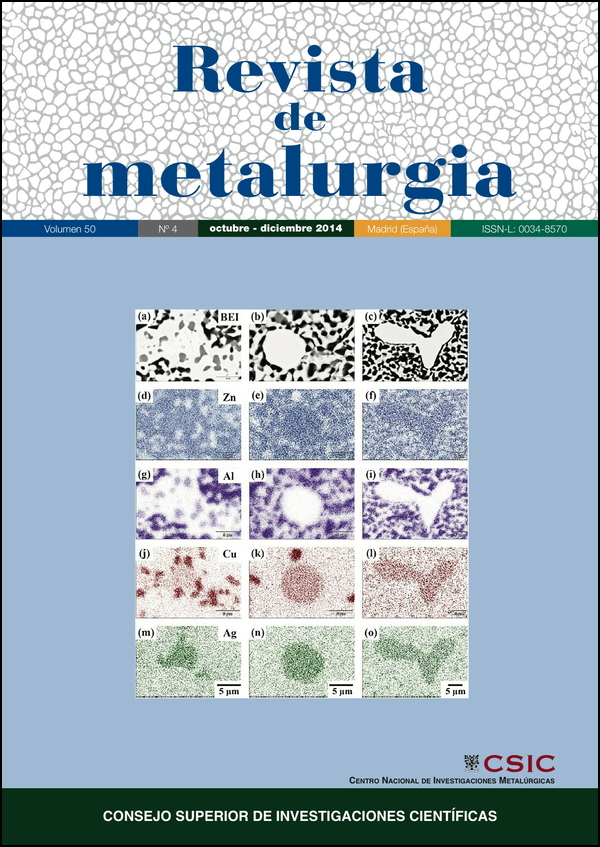

The study of phase transformations that take place in Zn-22%Al-2%Cu and Zn-22%Al-2%Cu-X (X = 1, 2 and 3%Ag) alloys was carried out using X-Ray Diffraction (XRD) and Scanning Electron Microscopy (SEM). Alloys were homogenized at 350 °C during 10 days and quenched at ~2 °C. Subsequently, samples were aged at 200 °C for different times. The initial microstructure consists in a matrix of fine equiaxial grains of α and η phases for all the alloys. Besides isolated particles of ε and Φ were observed without and with Ag addition, respectively. During the aging, the four phase reaction, α + ε→η + τ’, takes place to obtain the equilibrium η, α and τ’ phases. However, the Ag addition promotes the formation of the Φ phase, which retards or inhibits the four phase reaction. The stability of the Φ phase is obtained with 3%Ag, which could improve the dimensional stability of the alloy for future industrial applications.

Downloads

References

Avner Sydney, H. (1988). Introducción a la Metalurgia Física, 2ª ed., Mc Graw Ed., Hill, USA, p. 197.

Baker, H. (1992). ASM Metals Handbook, Vol. 3, Alloy Phase Diagram, ASM International, USA, pp. 56, 40, 182.

Casolco, S., Negrete-Sánchez, J., Torres-Villaseñor, G. (2003). Influence of silver on the mechanical properties of Zn-Al eutectoid superplastic alloy. Mater. Charact. 51 (1), 63–67. http://dx.doi.org/10.1016/j.matchar.2003.09.011

Casolco, S., López-Parra, M., Torres-Villaseñor, G. (2006). High strain rate superplasticity of a Zn–22wt.%Al–x wt.%Ag alloys. J. Mater. Process. Tech. 174 (1–3), 389–393. http://dx.doi.org/10.1016/j.jmatprotec.2005.02.271

Ciach, R., Król, J., Wegrzyn-Tasior, K. (1969). Studies on Four Phases Transformation in AlZn78 Alloy Containing 1–3 percent of Copper. Bull. Acad. Pol. Sci. Sér. Sci. Tech. 17 (4), 13.

Dorantes Rosales, H.J. (2000). Estudio de las transformaciones de fase de la aleación Zn-22%Al-2%Cu, Tesis Doctoral, Escuela Superior de Ingeniería Química e Industrias Extractivas, Instituto Politécnico Nacional, México.

Dorantes-Rosales, H., López-Hirata, V., Hua Zhu, Y. (1999). Decomposition process in Zn-22wt%Al-2%wt Cu alloy. Mater. Sci. Eng. A, 271 (1–2), 366–370. http://dx.doi.org/10.1016/S0921-5093(99)00255-5

Dorantes-Rosales, H., López-Hirata, V., Moreno-Palmerin, J., Cayetano-Castro, N., Saucedo-Muñoz, M., Torres Castillo, A. (2007). β' phase decomposition in Zn-22mass%Al and Zn-22mass%Al-2mass%Cu alloys at room temperature. Mater. Trans. 48 (10), 2791–2794. http://dx.doi.org/10.2320/matertrans.MRP2007058

Fawzy, A., Nada, R.H. (2006). Effect of grain diameter on the tensile characteristics of thermally deformed Ag4.4 wt% Cu alloy. Physica B. 371 (1), 5–11. http://dx.doi.org/10.1016/j.physb.2005.08.045

Gervais, E., Levert, H., Bees, M. (1980). American Foundry-men's Society, 84th Casting Congress and Exhibition, St. Louis, MO, USA.

Hillert, M. (1998). Phase Equilibria. Phase Diagrams and Phase Transformations, their thermodynamic basis, Ed. Cambridge University Press, New York, USA, pp. 294–296.

Houghton, M.E., Murray, M.T. (1984). An introduction to Zinc Alloys. Met. Forum 6 (4), 211–225.

Lohberg, K. (1983). Über das System Zinn-Antimon-Indium. Metall. 74, 456–457.

McNelley, T.R. (2010). Procesado por fricción batida (FSP): afino de la microestructura y mejora de propiedades, Rev. Metal. 46 (No. Extra), 149–156.

Murphy, S. (1975). The structure of the T'phase in the system. A1-Cu-Zn. Met. Sci. 9 (1), 163–168. http://dx.doi.org/10.1179/030634575790444414

Murphy, S. (1980). Solid-phase reactions in the low copper part of the Al-Cu-Zn system. Z. Metallkde 71 (2), 96–102.

Mykura, N., Zhu, H., Murphy, S. (1986). Solid-State Reactions in Zn-Al Based Alloys. Can. Metall. Quart. 25 (2), 152–159. http://dx.doi.org/10.1179/cmq.1986.25.2.151

Pérez-Prado, M.T., Ibáñez, J., Morris, M., Cristina, M.C., Ruano, O.A., González-Doncel, G. (1998). Estructura y textura de la fase Al3CaZn en una chapa laminada de la aleación superplástica Al-5 % Ca-5 % Zn. Rev. Metal. 34 (No. Extra), 324–328.

Rivas-López, D. (2001). Evolución microestructural durante la deformación plástica de la aleación Zn-22%Al-2%Cu, Tesis de licenciatura, Escuela Superior de Ingeniería Química e Industrias Extractivas, Instituto Politécnico Nacional, México.

Ruano, O. (1982). Superplasticidad. Rev. Metal. 18, 275–285.

Torres-Villaseñor, G., Negrete, J., Valdés, I. (1985). Propiedades y usos del Zinalco. Rev. Mex. Fís. 31 (3), 489–501.

Torres-Villaseñor, G., Negrete, J. (1994). Recent Advances in Science, Technology and Applications of Zn-Al Alloys, Proc. 3rd International Conference of Zn-Al Alloys, Distrito Federal, México.

Zhu, Y.H. (1994). Phase Transformations of Eutectoid Zn-Al Alloys, Proc. 3rd International Conference of Zn-Al Alloys, Recent Advances in Science, Technology and Applications of Zn-Al Alloys, Distrito Federal, México.

Zhu, Y.H. (1999). Microstructure dependence of damping behavior of eutectoid Zn-Al based alloy (ZA27). J. Mater. Sci. Technol. 15 (2), 178–180.

Zhu, Y.H. (2004). General rule of phase decomposition of Zn-Al based alloys (II)–One effects of external stress on phase transformation. Mater. Trans. 45 (11), 3083–3097. http://dx.doi.org/10.2320/matertrans.45.3083

Published

How to Cite

Issue

Section

License

Copyright (c) 2014 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.