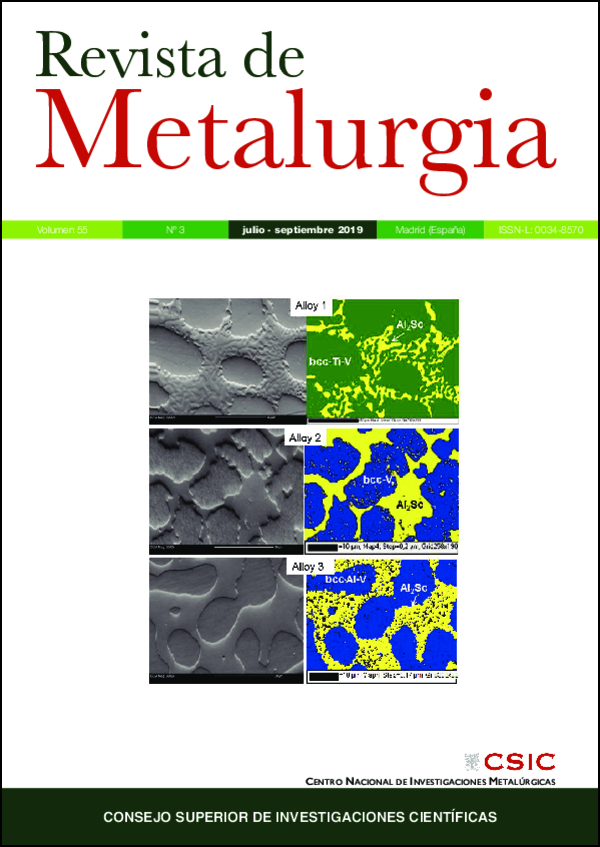

Design and characterization of three light-weight multi-principal-element alloys potentially candidates as high-entropy alloys

DOI:

https://doi.org/10.3989/revmetalm.147Keywords:

High entropy alloys, Microanalysis, Microscopy, Microstructure, ToughnessAbstract

The feasibility of preparing high entropy alloys in the Al-Sc-Ti-V-Cr system has been evaluated taking into account the different criteria reported in the literature. Based on such criteria, three Al-Sc-Ti-V-Cr alloys were chosen with contents of each element varying from 10 to 35 at. %, and prepared by arc melting. All alloys exhibit a two-phase dendritic microstructure, with the major dendritic phase being a bcc solid solution enriched in Ti, V, or Cr. Scandium is strongly rejected from the dendrites towards the interdendritic regions to form Al2Sc in the three alloys. The bcc solid solution dendrites become harder with high Ti content and lower with high Cr content. The toughness of the alloys depends on the hardness of the dendrites, with alloys with harder dendrites becoming more brittle. The results indicate that neither empirical criteria used nor THERMOCALC calculus tool can predict properly the formation of a single solid solution nor the nature of the existing phases respectively.

Downloads

References

Andersson, J.-O., Helander, T., Höglund, L., Shi, P., Sundman, B. (2002). Thermo-CAlc & DICTRA, Computational tools for materials science. Calphad 26 (2), 273-312. https://doi.org/10.1016/S0364-5916(02)00037-8

Anstis, G.R., Chantikul, P., Lawn, B.R., Marshall. D.B. (1981). A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. Am. Ceram. Soc. 64 (9), 533-538. https://doi.org/10.1111/j.1151-2916.1981.tb10320.x.

Cantor, B. (2011). High-entropy alloys. In: Encyclopedia of materials: Science and Technology. K.H.J. Buschow, R.W. Cahn, M.C. Flemings, B. Ilschner, E.J. Kramer, S. Mahajan, P. Veyssiere (Editors), Elsevier, Pergamon, pp. 1.3.

Cantor, B., Chang, I.T.H., Knight, P., Vincent, A.J.B. (2004). Microstructural development in equiatomic multicomponent alloys. Mat. Sci. Eng. A 375-377, 213-218. https://doi.org/10.1016/j.msea.2003.10.257

Cantor, B., Audebert, F., Galano, M., Kim, K.B., Stone, I.C., Warren, P.J. (2005). Novel Multicomponent Alloys. J. Metastab. Nanocryst. Mater. 24-25, 1-6. https://doi.org/10.4028/www.scientific.net/JMNM.24-25.1

Fu, Z., Chen, W., Wen, H., Zhang, D., Chen, Z., Zheng, B., Zhou, Y., Lavernia, E.J. (2016). Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 107, 59-71. https://doi.org/10.1016/j.actamat.2016.01.050

Guo, S., Liu, C.T. (2011). Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. 21 (6), 433-446. https://doi.org/10.1016/S1002-0071(12)60080-X

Kumar, A., Gupta, M. (2016). An Insight into Evolution of Light Weight High Entropy Alloys: A Review. Metals 6 (9), 1-19 . https://doi.org/10.3390/met6090199

Lu, Z.P., Wang, H., Chen, M.W., Baker, I., Yeh, J.W., Liu, C.T., Nieh, T.G. (2015). An assessment on the future development of high-entropy alloys: Summary from a recent workshop. Intermetallics 66, 67-76. https://doi.org/10.1016/j.intermet.2015.06.021

Miracle, D.B., Senkov, O.N. (2017). A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448-511. https://doi.org/10.1016/j.actamat.2016.08.081

Morris, D.G., Leboeuf, M., Morris, M.A. (1998). Hardness and toughness of MoSi2 and MoSi2-SiC composite prepared by reactive sintering of powders. Mat. Sci. Eng. A 251 (1-2), 262-268. https://doi.org/10.1016/S0921-5093(98)00517-6

Pickering, E.J., Jones, N.G. (2016). High entropy alloys: a critical assessment of their founding principles and future prospects. Int. Mater. Rev. 61 (3), 183-202. https://doi.org/10.1080/09506608.2016.1180020

Poletti, M.G., Battezzati, L. (2014). Electronic and thermodynamic criteria for the occurrence of high entropy alloys in metallic systems. Acta Mater. 75, 297-306. https://doi.org/10.1016/j.actamat.2014.04.033

Ren, B, Liu, Z.X., Li, D.M., Shi, L., Cai, B., Wang, M.X. (2010). Effect of elemental interaction on microstructure of CuCrFeNiMn high entropy alloy system. J. Alloy Compd. 493 (1-2), 148-153. https://doi.org/10.1016/j.jallcom.2009.12.183

Takeuchi, A., Inoue, A. (2005). Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 46 (12), 2817-2829. https://doi.org/10.2320/matertrans.46.2817.

Toda-Caraballo, I., Rivera Díaz-del-Castillo, P.E. (2016). A criterion for the formation of high entropy alloys based on lattice distortion. Intermetallics 71, 76-87. https://doi.org/10.1016/j.intermet.2015.12.011

Wu, W.-H., Yang, C.C., Yeh, J.W. (2006). Industrial development of high-entropy alloys. Ann. Chim. - Sci. Mat. 31 (6), 737-747. https://doi.org/10.3166/acsm.31.737-747

Yang, X., Zhang, Y. (2012) Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132 (2-3), 233-238. https://doi.org/10.1016/j.matchemphys.2011.11.021

Yang, X., Zhang, Y., Liaw, P.K. (2012). Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys. Procedia Engineer. 36, 292-298. https://doi.org/10.1016/j.proeng.2012.03.043

Ye, Y.F., Liu, C.T., Yang, Y. (2015). A geometric model for intrinsic residual strain and phase stability in high entropy alloys. Acta Mater. 94, 152-161. https://doi.org/10.1016/j.actamat.2015.04.051

Yeh, J.W., Chen, S.K., Lin, S.J., Gan, J.Y., Chin, T.S., Shun, T.T., Tsau, C.H., Chang, S.Y. (2004). Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 6 (5), 299-303. https://doi.org/10.1002/adem.200300567

Youssef, K.M., Zaddach, A.J., Niu, C., Irving, D.L., Koch, C.C. (2015). A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures. Mater. Res. Lett. 3 (2), 95-99. https://doi.org/10.1080/21663831.2014.985855

Yue, M.T., Xie, H., Lin, X., Yang, H., Meng, G. (2013). Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying. Entropy 15 (7), 2833-2845. https://doi.org/10.3390/e15072833

Zhang, Y., Zhou, Y.J., Lin, J.P., Chen, G.L., Liaw, P.K. (2008). Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 10 (6), 534-538. https://doi.org/10.1002/adem.200700240

Zhang, K., Fu, Z. (2012). Effects of annealing treatment on phase composition and microstructure of CoCrFeNiTiAlx high-entropy alloys. Intermetallics 22, 24-32. https://doi.org/10.1016/j.intermet.2011.10.010

Zhang, Y., Yang, X., Liaw, P.K. (2012). Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 64 (7), 830-838. https://doi.org/10.1007/s11837-012-0366-5

Zhang, Y., Zuo, T.T., Tang, Z., Gao, M.C., Dahmen, K.A., Liaw, P.K., Lu, Z.P. (2014). Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1-93. https://doi.org/10.1016/j.pmatsci.2013.10.001

Published

How to Cite

Issue

Section

License

Copyright (c) 2019 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.