Diseño y caracterización de tres aleaciones multiprincipales ligeras potencialmente candidatas a aleaciones de alta entropía

DOI:

https://doi.org/10.3989/revmetalm.147Palabras clave:

Alta entropía, Microanálisis, Microestructura, Microscopía, TenacidadResumen

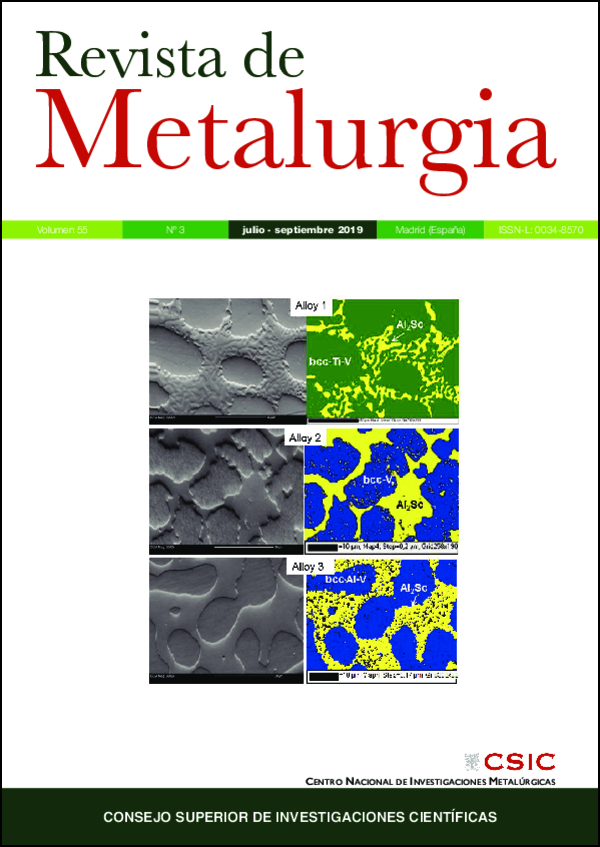

En este trabajo se estudia la posibilidad de preparar aleaciones de alta entropía del sistema Al-Sc-Ti-V-Cr. Para ello se han seleccionado los elementos y la composición utilizando los criterios conocidos y disponibles en la literatura y se han preparado mediante fusión por arco tres aleaciones con contenidos que varían entre el 10 y 35 at.%. Las tres aleaciones tienen una microestructura dendrítica bifásica similar, siendo las dendritas una solución sólida bcc enriquecida en Ti, V o Cr. El escandio aparece únicamente en el espacio interdendrítico formando el intermetálico Al2Sc. La dureza de las dendritas crece con el contenido en Ti y se hace menor a medida que es mayor el contenido en Cr. Además, la tenacidad de las aleaciones depende de la dureza de las dendritas siendo ésta mayor cuanto más blandas son las dendritas. Los resultados obtenidos demuestran que ni los criterios empíricos utilizados ni los cálculos mediante THERMOCALC permiten predecir la formación de una única solución sólida ni la naturaleza de las fases observadas experimentalmente.

Descargas

Citas

Andersson, J.-O., Helander, T., Höglund, L., Shi, P., Sundman, B. (2002). Thermo-CAlc & DICTRA, Computational tools for materials science. Calphad 26 (2), 273-312. https://doi.org/10.1016/S0364-5916(02)00037-8

Anstis, G.R., Chantikul, P., Lawn, B.R., Marshall. D.B. (1981). A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. Am. Ceram. Soc. 64 (9), 533-538. https://doi.org/10.1111/j.1151-2916.1981.tb10320.x.

Cantor, B. (2011). High-entropy alloys. In: Encyclopedia of materials: Science and Technology. K.H.J. Buschow, R.W. Cahn, M.C. Flemings, B. Ilschner, E.J. Kramer, S. Mahajan, P. Veyssiere (Editors), Elsevier, Pergamon, pp. 1.3.

Cantor, B., Chang, I.T.H., Knight, P., Vincent, A.J.B. (2004). Microstructural development in equiatomic multicomponent alloys. Mat. Sci. Eng. A 375-377, 213-218. https://doi.org/10.1016/j.msea.2003.10.257

Cantor, B., Audebert, F., Galano, M., Kim, K.B., Stone, I.C., Warren, P.J. (2005). Novel Multicomponent Alloys. J. Metastab. Nanocryst. Mater. 24-25, 1-6. https://doi.org/10.4028/www.scientific.net/JMNM.24-25.1

Fu, Z., Chen, W., Wen, H., Zhang, D., Chen, Z., Zheng, B., Zhou, Y., Lavernia, E.J. (2016). Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater. 107, 59-71. https://doi.org/10.1016/j.actamat.2016.01.050

Guo, S., Liu, C.T. (2011). Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog. Nat. Sci. 21 (6), 433-446. https://doi.org/10.1016/S1002-0071(12)60080-X

Kumar, A., Gupta, M. (2016). An Insight into Evolution of Light Weight High Entropy Alloys: A Review. Metals 6 (9), 1-19 . https://doi.org/10.3390/met6090199

Lu, Z.P., Wang, H., Chen, M.W., Baker, I., Yeh, J.W., Liu, C.T., Nieh, T.G. (2015). An assessment on the future development of high-entropy alloys: Summary from a recent workshop. Intermetallics 66, 67-76. https://doi.org/10.1016/j.intermet.2015.06.021

Miracle, D.B., Senkov, O.N. (2017). A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448-511. https://doi.org/10.1016/j.actamat.2016.08.081

Morris, D.G., Leboeuf, M., Morris, M.A. (1998). Hardness and toughness of MoSi2 and MoSi2-SiC composite prepared by reactive sintering of powders. Mat. Sci. Eng. A 251 (1-2), 262-268. https://doi.org/10.1016/S0921-5093(98)00517-6

Pickering, E.J., Jones, N.G. (2016). High entropy alloys: a critical assessment of their founding principles and future prospects. Int. Mater. Rev. 61 (3), 183-202. https://doi.org/10.1080/09506608.2016.1180020

Poletti, M.G., Battezzati, L. (2014). Electronic and thermodynamic criteria for the occurrence of high entropy alloys in metallic systems. Acta Mater. 75, 297-306. https://doi.org/10.1016/j.actamat.2014.04.033

Ren, B, Liu, Z.X., Li, D.M., Shi, L., Cai, B., Wang, M.X. (2010). Effect of elemental interaction on microstructure of CuCrFeNiMn high entropy alloy system. J. Alloy Compd. 493 (1-2), 148-153. https://doi.org/10.1016/j.jallcom.2009.12.183

Takeuchi, A., Inoue, A. (2005). Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element. Mater. Trans. 46 (12), 2817-2829. https://doi.org/10.2320/matertrans.46.2817.

Toda-Caraballo, I., Rivera Díaz-del-Castillo, P.E. (2016). A criterion for the formation of high entropy alloys based on lattice distortion. Intermetallics 71, 76-87. https://doi.org/10.1016/j.intermet.2015.12.011

Wu, W.-H., Yang, C.C., Yeh, J.W. (2006). Industrial development of high-entropy alloys. Ann. Chim. - Sci. Mat. 31 (6), 737-747. https://doi.org/10.3166/acsm.31.737-747

Yang, X., Zhang, Y. (2012) Prediction of high-entropy stabilized solid-solution in multi-component alloys. Mater. Chem. Phys. 132 (2-3), 233-238. https://doi.org/10.1016/j.matchemphys.2011.11.021

Yang, X., Zhang, Y., Liaw, P.K. (2012). Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys. Procedia Engineer. 36, 292-298. https://doi.org/10.1016/j.proeng.2012.03.043

Ye, Y.F., Liu, C.T., Yang, Y. (2015). A geometric model for intrinsic residual strain and phase stability in high entropy alloys. Acta Mater. 94, 152-161. https://doi.org/10.1016/j.actamat.2015.04.051

Yeh, J.W., Chen, S.K., Lin, S.J., Gan, J.Y., Chin, T.S., Shun, T.T., Tsau, C.H., Chang, S.Y. (2004). Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 6 (5), 299-303. https://doi.org/10.1002/adem.200300567

Youssef, K.M., Zaddach, A.J., Niu, C., Irving, D.L., Koch, C.C. (2015). A Novel Low-Density, High-Hardness, High-entropy Alloy with Close-packed Single-phase Nanocrystalline Structures. Mater. Res. Lett. 3 (2), 95-99. https://doi.org/10.1080/21663831.2014.985855

Yue, M.T., Xie, H., Lin, X., Yang, H., Meng, G. (2013). Microstructure of Laser Re-Melted AlCoCrCuFeNi High Entropy Alloy Coatings Produced by Plasma Spraying. Entropy 15 (7), 2833-2845. https://doi.org/10.3390/e15072833

Zhang, Y., Zhou, Y.J., Lin, J.P., Chen, G.L., Liaw, P.K. (2008). Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 10 (6), 534-538. https://doi.org/10.1002/adem.200700240

Zhang, K., Fu, Z. (2012). Effects of annealing treatment on phase composition and microstructure of CoCrFeNiTiAlx high-entropy alloys. Intermetallics 22, 24-32. https://doi.org/10.1016/j.intermet.2011.10.010

Zhang, Y., Yang, X., Liaw, P.K. (2012). Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 64 (7), 830-838. https://doi.org/10.1007/s11837-012-0366-5

Zhang, Y., Zuo, T.T., Tang, Z., Gao, M.C., Dahmen, K.A., Liaw, P.K., Lu, Z.P. (2014). Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1-93. https://doi.org/10.1016/j.pmatsci.2013.10.001

Publicado

Cómo citar

Número

Sección

Licencia

Derechos de autor 2019 Consejo Superior de Investigaciones Científicas (CSIC)

Esta obra está bajo una licencia internacional Creative Commons Atribución 4.0.

© CSIC. Los originales publicados en las ediciones impresa y electrónica de esta Revista son propiedad del Consejo Superior de Investigaciones Científicas, siendo necesario citar la procedencia en cualquier reproducción parcial o total.

Salvo indicación contraria, todos los contenidos de la edición electrónica se distribuyen bajo una licencia de uso y distribución “Creative Commons Reconocimiento 4.0 Internacional ” (CC BY 4.0). Consulte la versión informativa y el texto legal de la licencia. Esta circunstancia ha de hacerse constar expresamente de esta forma cuando sea necesario.

No se autoriza el depósito en repositorios, páginas web personales o similares de cualquier otra versión distinta a la publicada por el editor.