Wear behaviour of coatings of aluminium matrix composites fabricated by thermal spray method

DOI:

https://doi.org/10.3989/revmetalm.2007.v43.i5.80Keywords:

Plasma-spray, Composites, Aluminium matrix, Sol-gel coatings, WearAbstract

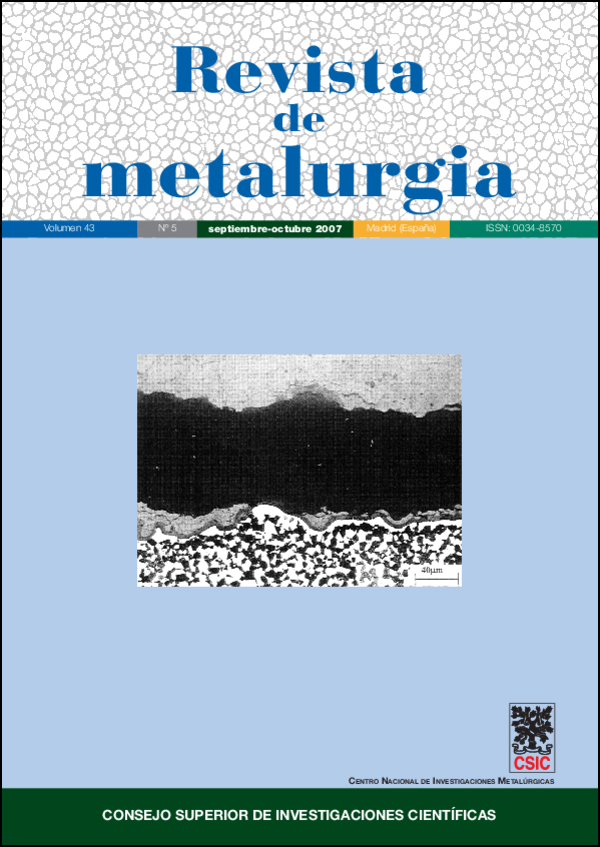

In this work, the wear behaviour of coatings made of aluminium matrix composites reinforced with 20% of SiC particles and manufactured by thermal spray method with oxyacetylene flame has been investigated. The wear behaviour between coatings with uncoated particles and sol-gel silica coated ones heat treated at 500 °C and 725 °C have been compared. The sprayed coatings with silica coated particles are more homogenous and less porous due to increase of wettability by molten aluminium that takes place on coated particles. The microstructure of the sprayed coatings, the wear surfaces and the wear debris have been anlysed using optical microscopy, scanning electron microscopy and microanalysis techniques (EDX). The results show a smaller wear rate, a lower friction coefficient and more reduced loss of mass for the coatings sprayed with particles with sol-gel silica coatings than those made with uncoated particles.

Downloads

References

[1] P. Rodrigo, P. Poza, M.V. Utrilla y A.Ureña, Rev. Metal. Madrid 41 (2005) 298-307.

[2] A. Forn-Alonso, M.T. Baile-Puig y Rupérez-De-Gracia, Rev. Metal. Madrid Vol. Extr. (2005)193-196.

[3] J.A. Picas, A. Forn, R. Rilla y E. Martín, Rev. Metal. Madrid Vol. Extr. (2005)197-201.

[4] H. Eschnauer y E. Lugscheider, Metall. 45 (1991) 458-456.

[5] J.C. Viala, P. Portier y J. Bouix, J. Mat. Sci. 25 (1990) 1.842-1.852.

[6] J. Rams, M. Campo y A. Ureña, Adv Eng. Mat. 6 (2004) 57-61.

[7] A. Ureña, J. Rams, M. D. Escalera y M. Campo, Bol. Soc. Esp. Ceram. 43 (2004) 135-138.

[8] J. Rams, M. Campo y A. Ureña, J. Mat. Res. 19 (2004) 2.109-2.116.

[9] M. Campo, A. Ureña y J. Rams, Scripta. Mat. 52 (2005) 977-982.

[10] A. Pardo, M. C. Merino, J. Rams, S. Merino, F. Viejo y M. Campo, Oxid. Met. 63 (2005) 215-227. doi:10.1007/s11085-005-3201-3

[11] M. Campo, J. Rams y A. Ureña, Bol. Soc. Esp. Ceram. 44 (2005) 270-277.

[12] M. Campo, B. Torres, A. Ureña y J. Rams, Proc. IX Congreso Nacional de Materiales, Vol.1, Vigo, España (2006), Servicio de Publicaciones de la Universidad de Vigo (Eds.), Vigo, España (2006), pp. 425-428.

[13] J.F. Archard, J. Appl. Phys. 24 (1953) 981-988. doi:10.1063/1.1721448

[14] J.C. Lee, J.P. Ahn, J.H. Shim, Z. Shi y H.I. Lee, Scripta. Mat. 41 (1999) 895.

[15] A. Ureña, J. Rams, M. Campo y M. Sánchez, Rev. Metal. Madrid Vol. Extr. (2005) 395-400.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2007 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.