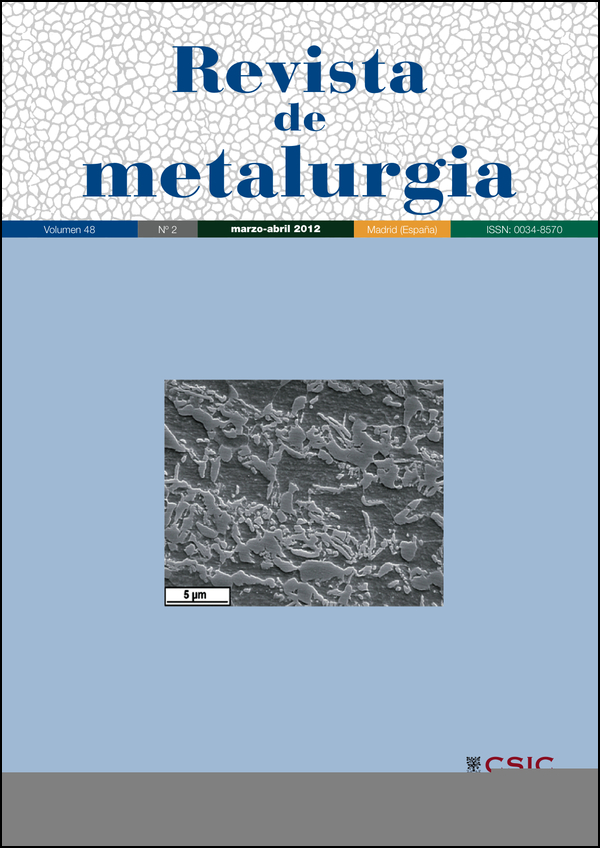

High temperature corrosion of 9Cr-1Mo ferritic steel P91 modified, in oxidizing-carburizing atmospheres

DOI:

https://doi.org/10.3989/revmetalm.1139Keywords:

Oxidation, carburization simultaneous, 9Cr-1Mo modified steel, High temperature corrosion, Solid state diffusionAbstract

High temperature corrosion in processing units of the chemical, petrochemical, and thermoelectric carbochemical is of high interest, due to the costs generated by sudden failures caused by deterioration in the mechanical properties of metals, being the carburization of the metallic matrix the most important corrosion mechanism resulting in loss of ductility and creep resistance. In this research a 9Cr-1Mo modified steel P91 was exposed to simulated atmospheres oxidant-fuel gas mixtures simultaneous in equilibrium of CO, CO2, CH4, H2O and H2, similar to those produced in the refining industry, at temperatures between 550 and 750 ºC. The microstructural evolution of the metal matrix was analyzed, also the growth, evolution and behavior of oxide layers and carburized, establishing the mechanism of deterioration of the material and the extent of damage for times exceeding 700 h of exposure.

Downloads

References

[1] R. Viswanathan, W.T. Bakker y J.D. Parker, Advances in Material Technology for Fossil Power Plants, Ed. Maney Materials Science, Londres, Inglaterra, 2001, pp.187-196.

[2] M. Thiele, H. Teichmann, W. Schwarz y W.J. Quadakkers, VGB Kraftwerkstech 77 (1997) 129-134.

[3] M. Thiele, H. Teichmann, W. Schwarz y W.J. Quadakkers, VGB Kraftwerkstech 2 (1997) 129.

[4] K. Zabelt, B. Melzer y A. Reuter, Proceedings Korrosion in Kraftwerken, Vol. 11, Wurzburgo, Alemania, 1999, pp. 99–111.

[5] J. Y. Liu y S. C. Chang, Corros. Sci. 39 (1997) 1021-1035. http://dx.doi.org/10.1016/S0010-938X(96)00083-2

[6] W.J. Quadakkers, M. Thiele, P.J. Ennis, H. Teichmann y W. Schwarz, Proceedings EUROCORR 97, Vol. 2, Trondheim, Norway, 1997, P.S. Jackman y L.M. Smith (Eds.), Londres, Inglaterra, 1999, pp. 35-40.

[7] I. Wolf, H.J. Grabke y D. Schmidt, Oxid. Met. 29 (1988) 289-306. http://dx.doi.org/10.1007/BF00751801

[8] A. Rahmel y J. Tobolski, Corros. Sci. 5 (1965) 333-346. http://dx.doi.org/10.1016/S0010-938X(65)90500-7

[9] S. Ling, T.A. Ramanarayanan y R. Petrovic-Luton, Oxid. Met. 40 (1993) 179-196. http://dx.doi.org/10.1007/BF00665264

[10] P. Kofstad, Proc. High Temperature Corrosion, Ed. Elsevier Applied Science Publishers Ltd, Londres, Inglaterra, 1988, pp. 246-546.

[11] A.S. Khanna, P. Rodriguez y J.B. Gnanamoorthy, Oxid. Met. 26 (1986) 171-200. http://dx.doi.org/10.1007/BF00659183

[12] C. T. Fujii y R. A. Meussner, J. Electrochem. Soc. 110 (1963) 1195-1204. http://dx.doi.org/10.1149/1.2425624

[13] R.A. Perkins, Proc. High Temperature Corrosion, Vol. 6, R.A. Rapp (Ed.), NACE, Houston, EE.UU., 1983, p. 345.

[14] P. Ganesan, G.D. Smith y C.S. Tassen, Proc.Corrosion/95, Paper 470, NACE, Houston, EE.UU.,1995.

[15] T. Sasaki, K. Kobayashi, T. Yamaura, T. Kasuya y T. Masuda, Kurashiki 25 (1991) 78-87.

[16] R. Viswanathan, M. Berasi, J. Tanzosh y T. Thaxton, Proc. P.V.P., Vol. 201, Nashville, Tennessee, M. Prager y C. Cantzler (Eds), ASME, New York, EE.UU., 1990, pp. 97- 104.

[17] M. J. Bennett y J.B. Price, J. Mater. Sci. 16 (1981) 170-188. http://dx.doi.org/10.1007/BF00552071

[18] R.W Swindeman, V.K Sikka, P.J Maziasz y D. A Canonico, Proc. P.V.P., Vol. 374, San Diego, California, 1998, H.S. Mehta, W.H. Bamford et al. (Eds), ASME, New York, EE.UU., 1998, pp. 305-312.

[19] D.C. Agarwal, U. Brill y Klöwer, Proc. Corrosion/95, Paper 471, NACE, Houston, EE.UU., 1995, p. 8.

[20] H. J. Grabke y I. Wolf, Mat. Sci. Eng. 87 (1987) 23-33. http://dx.doi.org/10.1016/0025-5416(87)90357-0

[21] H.J. Grabke y D.B. Meadowcroft, Guidelines for Methods of Testing and Research in High Temperature Corrosion, European Federation of Corrosion Publications, Londres, Inglaterra, 1995, pp. 11-36.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2012 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.