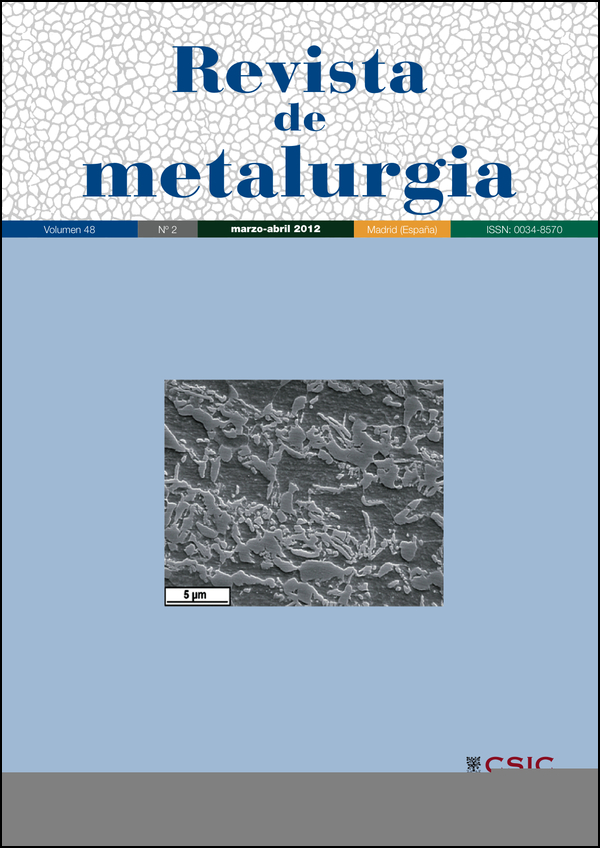

Austenite-to-pearlite isothermal decomposition mechanisms in a 0.44C-0.73Mn steel

DOI:

https://doi.org/10.3989/revmetalm.1161Keywords:

Isothermal decomposition of austenite, Interlamellar spacing, Divergent pearlite, Kinetics of pearlitic formationAbstract

The goal of this paper is to determine the austenite-to-pearlite isothermal decomposition mechanisms in a 0.44C-0.73 Mn steel. More precisely, the role of austenitizing temperature (Tγ), and hence the austenitic grain size (AGS), in the kinetics of pearlite formation has been studied. Results allow us to conclude that the average size of pearlitic colonies is increased as the AGS is increased. On the other hand, it appears that the interlamellar spacing of the pearlite does not depend on the Tγ but is controlled by the isothermal decomposition temperature of austenite (T). Finally, it was found that formation of pearlite is triggered for small AGS values and isothermal decomposition temperature regimes where the predominant controlling mechanism is due to carbon volume diffusion.

Downloads

References

[1] J. Fridberg y M. Hillert, Acta Metallurgica 18 (1970) 1.253-1.260.

[2] C. Capdevila, F.G. Caballero y C. García de Andrés, Acta Mater. 50 (2002) 4.629-4.641.

[3] J. Herian y K. Aniolek, Archives of Materials Science and Engineering 31 (2) (2008) 83-86.

[4] S. Allain, M. Gouné, O. Bouaziz, E. Kassir, P. Barges y L. Jantzen, Mater. Sci. 46 (2011) 2.764-2.770.

[5] X. Zhang, A. Godfrey, X. Huang, N. Hansen y Q. Liu, Acta Mater. 59 (2011) 3.422-3.430.

[6] K. George, Steels - Processing, Structure, and Performance, ASM International, Ohio, EE.UU., 2005, pp. 281-285.

[7] R.W.K. Honeycombe y H.K.D.H. Bhadeshia, Steels, Microstructures and Properties, Butterworths-Heinemann (Elsevier), London, England, 2006, p. 52.

[8] N. Ridley, Phase Transformation in Ferreous Alloys, TMS-AIME, Warrendale, EE.UU., 1984, p. 201.

[9] C. Capdevila, F.G. Caballero y C. García de Andrés, Scripta Materialia 44 (2001) 593-600. http://dx.doi.org/10.1016/S1359-6462(00)00647-3

[10] MTDATA National Physical Laboratory, at www.npl.co.uk/mtdata/ (acceso Agosto 2011), Teddington, England, 2003.

[11] C. García de Andrés, M.J. Bartolomé, C. Capdevila, D.S. Martín, F.G. Caballero y V. López, Mater. Charact. 46 (2001) 389-398. http://dx.doi.org/10.1016/S1044-5803(01)00142-5

[12] IMAGE TOOL, University of Texas, at ddsdx.uthscsa.edu/dig/itdesc.html (acceso Octubre 2011), San Antonio, EE.UU., 2002.

[13] O. Grässel, L. Kru.ger, G. Frommeyer y L. W. Meyer, International Journal of Plasticity 16 (2000) 1.391-1.409.

[14] F.G. Caballero, C. García de Andrés y C. Capdevila, Mater. Charact. 45 (2000) 111-116. http://dx.doi.org/10.1016/S1044-5803(00)00056-5

[15] E.E. Underwood, Quantitative Stereology, Addison-Wesley Reading, Massachusetts, EE.UU., 1970.

[16] S.A. SALTYKOV, Stereometric Metallography, 2nd Ed., Metallurgizdat, Moscow, 1958.

[17] Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count E 562-02, ASTM International, PA, EE.UU.

[18] R.F. Mehl y W.C. Hagel, Progress in Metal Physics, Vol. 6, Pergamon Press, New York, EE.UU., 1956, p. 74.

[19] R.F. Mehl y W.C. Hagel, Decomposition of austenite by diffusional processes, V.F. Zackay y H.I. Aaronson (Eds.), Interscience, New York, EE.UU., 1962, p. 131.

[20] B. Thomas y M. Guttmann, The Book of steels, G. Béranger, G. Henry y G. Sanz (Eds.), SOLLAC, IRSID, Paris, France, 1996, p. 131.

[21] M. Hillert, Conferencia Internacional Solid Solid Phase Transformation, H.I. Aaronson et al. (Eds.), TMS-AIME, Warrendale, EE.UU., 1982, p. 789.

[22] C. Capdevila, F.G. Caballero y C. García de Andrés, Scripta Mater. 50 (2004) 175-177. http://dx.doi.org/10.1016/j.scriptamat.2003.09.015

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2012 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.