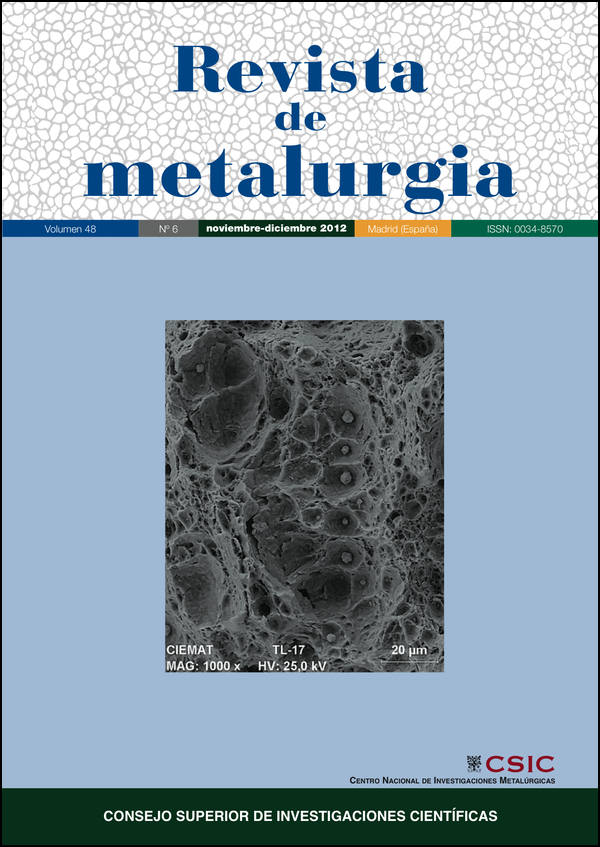

The cooling conditions effects on the fraction and morphology of the epsilon primary phase in an ACuZinc5TM commercial alloy

DOI:

https://doi.org/10.3989/revmetalm.1163Keywords:

Phase epsilon, Thermal analysis, Cooling conditions, ACuZinc5TM alloysAbstract

The mechanical properties of ACuZinc5TM alloys are influenced by the fraction solid of the primary epsilon (ε) phase and their interrelations with the eta (η) phase. In this study the primary epsilon phase fraction results from cooling conditions similar to that applied in different casting processes have been measured. Additionally an analysis was made from the morphology’s changes and from the thermal analysis results to suggest the probably adequate moment to apply stirring in semisolid metal processing. From these results it is possible to design experimental thermal cycles to obtain an adequate distribution of ε and η phases in the end castings microstructure.

Downloads

References

[1] M.S. Rashid y M.D. Hanna, US Patent Nº 4.990, 310 (1991).

[2] M.D. Hanna y M.S. Rashid, US Patent Nº 5.603, 552 (1997).

[3] H.I. Laukli, C.M. Gourlay y A.K. Dahle, Metall. Mater. Trans. A 36 (2005) 805.

[4] Z. Zhen, Ma Qian, S. Ji y Z. Fan, Scripta Mater. 54 (2006) 207-211. http://dx.doi.org/10.1016/j.scriptamat.2005.09.032

[5] M.C. Flemings, Metall. Mater. Trans. A 22 (1991) 952-981.

[6] O. Lashkari y R. Ghomashchi, J. Mater. Proc. Technol. 182 (2007) 229-240. http://dx.doi.org/10.1016/j.jmatprotec.2006.08.003

[7] D. Ma, Y. Li, S. C. NG y H. Jones. Acta Mater. 48 (2000) 1.741-1.751.

[8] L. Bäckerud, E. Krol y J. Tamminen, Solidification Characteristics of Aluminum Alloys, AFS/Skanaluminium, Oslo; Norway, 1986, pp. 63-74.

[9] L. Bäckerud, G. Chai y J. Tamminen, Solidification Characteristics of Aluminum Alloys Vol. 2, AFS/Skanaluminium, Sweden, 1990, pp. 95-101.

[10] L. Arnberg, L. Bäckerud y G. Chai, Solidification Characteristics of Aluminum Alloys Vol. 3 Dendrite Coherency, AFS, Illinois, 1996.

[11] L.M. Veldman, A. Dahle, D. H. StJohn y L. Arnberg, Metall. Mater. Trans. A 32 (2001) 147. http://dx.doi.org/10.1007/s11661-001-0110-1

[12] J. Oetinger, Die Casting Engineer, Julio (2002) 70-71.

[13] E.D. Jareño, S.I. Maldonado y F.A. Hernández, J. Alloys Compd. 490 (2010) 524-530. http://dx.doi.org/10.1016/j.jallcom.2009.10.073

[14] J. Haughton y K. Bingham, Proceedings of the Royal Society of London 99A, 1921, pp. 47-68.

[15] G. Ghosh y J. Humbeeck, Aluminium-Copper-Zinc, Ternary Alloys, V.C.H., Weinheim, Vol. 5, 1992, pp. 92-112.

[16] S. Murphy, Zeitschrift fuer Metallkunde, 71 (1980) 96-102.

[17] H. Liang y Y.A. Chang, Journal of Phase Equilibria 19 (1998) 25-37. http://dx.doi.org/10.1361/105497198770342724

[18] B.J. Li y C.G. Chao, Metall. Mater. Trans. A 30 (1999) 917-923. http://dx.doi.org/10.1007/s11661-999-0145-2

[19] W. Kurz, Fundamentals of Solidification, Fourth Edition, Trans. Tech Publications, 1998, p. 111.

[20] D.M. Stefanescu, Science and Engineering of Casting Solidification, Second Edition, Springer, 2009, pp. 247-257.

[21] S. Aoyama, C. Liu, T. Sakazawa y Y. Pan, US Patent 7,051,784 B2 (2006).

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2012 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.