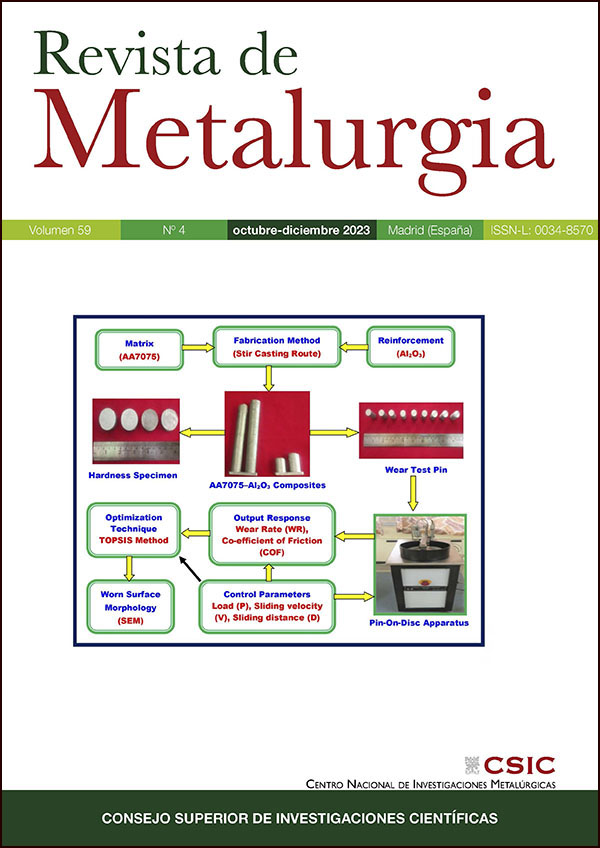

Investigations on microstructure, hardness and tribological behaviour of AA7075-Al2O3 composites synthesized via stir casting route

DOI:

https://doi.org/10.3989/revmetalm.253Keywords:

AA7075, Al2O3, Composites, Hardness, Stir casting, TOPSIS approach, Tribological behaviourAbstract

Aluminium matrix composite (AMC) materials play an important role in the field of automobile and aerospace industries due to their excellent properties. In this research, aluminium alloy (AA7075) was reinforced with alumina (Al2O3) particles to improve their hardness and tribological behaviour of the base alloy. Four composites were prepared by varying the content (4, 8 and 12 wt.%) of Al2O3 particles through the stir casting technique. The surface morphology of the proposed composites ensured the uniform distribution of Al2O3 particles into the matrix alloy. The hardness of the composite was measured using a Brinell hardness tester and the maximum value of hardness was found in the AA7075 - 8 wt.% Al2O3 composite. Hence, a tribological investigation was carried out on this AA7075 - 8 wt.% Al2O3 composite. Load (P), sliding speed (V) and sliding velocity (D) were taken as the wear parameters for conducting the experiments. A Technique for Order Preference by Similarity to Ideal Preferred Solution (TOPSIS) approach has been applied to find out the optimal conditions of parameters to obtain the lowest wear rate (WR) and the co-efficient of friction (COF). The results showed that the lowest WR and COF was obtained at ‘P’ of 15 N, ‘V’ of 1 m•s-1 and ‘D’ of 1000 m•s-1. ANOVA results revealed that ‘P’ is the factor with the most significant contribution (38.36%), followed by ‘D’ (28.32%). The worn surface morphology of the confirmation experiment specimen was investigated by SEM and the wear mechanism was reported.

Downloads

References

Alagarsamy, S.V., Raveendran, P., Ravichandran, M. (2020). Investigation of material removal rate and tool wear rate in spark erosion machining of Al-Fe-Si alloy composite using Taguchi coupled TOPSIS approach. Silicon. 13, 2529-2543. https://doi.org/10.1007/s12633-020-00596-x

Altinkok, N. (2013). Mechanical properties and wear behaviour of Al2O3/SiCp reinforced aluminium-based MMCs produced by the stir casting technique. Adv. Compos. Lett. 22 (4), 80-89. https://doi.org/10.1177/096369351302200402

Allasi, H.L., Soosaimariyan, M.V., Chidambaranathan, V.S. (2023). Wear behaviour of a Cu-Ni-Sn hybrid composite reinforced with B4C prepared by powder metallurgy technique. J. Mech. Eng. 69 (5-6), 275-283. https://doi.org/10.5545/sv-jme.2022.423

Azadeh, A., Kor, H., Hatefi, S.-M. (2011). A hybrid genetic algorithm-TOPSIS-computer simulation approach for optimum operator assignment in cellular manufacturing systems. J. Chin. Inst. Eng. 34 (1), 57-74. https://doi.org/10.1080/02533839.2011.552966

Balaji, S., Maniarasan, P., Alagarsamy, S. V., Alswieleh, A.M., Mohanavel, V., Ravichandran, M., Jeon, B.H., Allasi, H.L. (2022). Optimization and prediction of tribological behaviour of Al-Fe-Si alloy based nano grains refined composites using Taguchi with response surface methodology. J. Nanomater. 1-12, ID 9733264. https://doi.org/10.1155/2022/9733264

Baskaran, S., Anandakrishnan, V., Duraiselvam, M. (2014). Investigations on dry sliding wear behavior of in situ casted AA7075-TiC metal matrix composites by using Taguchi technique. Mater. Des. 60, 184-192. https://doi.org/10.1016/j.matdes.2014.03.074

Bharath, V., Nagaral., M., Auradi, V., Kori, S.A. (2014). Preparation of 6061Al-Al2O3 MMC's by stir casting and evaluation of mechanical and wear properties. Procedia. Mater. Sci. 6, 1658 - 1667. https://doi.org/10.1016/j.mspro.2014.07.151

Bhowmik, A., Dey, D., Biswas, A. (2021). Comparative study of microstructure, physical and mechanical characterization of SiC/TiB2 reinforced aluminium matrix composite. Silicon. 13, 2003-2010. https://doi.org/10.1007/s12633-020-00591-2

Dhanalakshmi, S., Mohanasundararaju, N., Venkatakrishnan, P.G., Karthik, V. (2018). Optimization of friction and wear behaviour of Al7075-Al2O3-B4C metal matrix composites using Taguchi method. IOP Conf. Series: Mater. Sci. Eng. 314, 012025. https://doi.org/10.1088/1757-899X/314/1/012025

Dharmalingam, S., Subramanian, R., Kok, M. (2013). Optimization of abrasive wear performance in aluminium hybrid metal matrix composites using Taguchi-grey relational analysis.Proc. Inst. Mech. Eng. J: J. Eng. Tribol. 227 (7), 749-760. https://doi.org/10.1177/1350650112467945

Halverson, D.C., Pyzik, A.J., Aksay, I.A., Snowden, E. (1989). A processing of boron carbid -aluminium composites. J. Am. Ceram. Soc. 72 (5), 775-780. https://doi.org/10.1111/j.1151-2916.1989.tb06216.x

Huda, A. Al-Salihi, Akram Mahmood, A., Hussain J. Alalkawi. (2019). Mechanical and wear behavior of AA7075 aluminum matrix composites reinforced by Al2O3 Nanoparticles. Nanocomposites. 5 (3), 67-73. https://doi.org/10.1080/20550324.2019.1637576

Jayakumar, E., Praveen, A.P., Rajan, T.P.D., Pai, B.C. (2018). Studies on tribological characteristics of centrifugally cast SiCp-reinforced functionally graded A319 aluminium matrix composites. Trans. Indian. Inst. Met. 71, 2741-2748. https://doi.org/10.1007/s12666-018-1442-5

Johny James, Jabanjalin, H., Ahaiter L. (2023). Study of tribological and mechanical properties of composite reinforced with tungsten carbide. AIP Conf. Proc. 2548 (1), 050007. https://doi.org/10.1063/5.0121012

Magibalan, S., Senthilkumar, P., Senthilkumar, C., Prabu, M. (2020). Optimization of wear parameters for aluminium 4% fly-ash composites. Indian J. Eng. Mater. Sci. 27, 458-464.

Mistry, J.M., Gohil, P.P. (2019). Experimental investigations on wear and friction behaviour of Si3N4p reinforced heat-treated aluminium matrix composites produced using electromagnetic stir casting process. Compos. Part B: Eng. 161, 190-204. https://doi.org/10.1016/j.compositesb.2018.10.074

Miyajima, T., Iwai, Y. (2003). Effects of reinforcements on sliding wear behaviour of aluminium matrix composites. Wear 255 (1-66), 606-616. https://doi.org/10.1016/S0043-1648(03)00066-8

Moustafa, E.B., Mikhaylovskaya, A.V., Taha, M.A., Mosleh, A.O. (2022). Improvement of the microstructure and mechanical properties by hybridizing the surface of AA7075 by hexagonal boron nitride with carbide particles using the FSP process. J. Mater. Res. Technol. 17, 1986-1999. https://doi.org/10.1016/j.jmrt.2022.01.150

Sahin, Y. (2007). Tribological behaviour of metal matrix and its composite. Mater. Des. 28, 1348-1352. https://doi.org/10.1016/j.matdes.2006.01.032

Sakthivelu, S., Sethusundaram, P.P., Meignanamoorthy, M., Ravichandran, M. (2018). Synthesis of metal matrix composites through stir casting process-a review. Mech. Mech. Eng. 22 (1), 357-370. https://doi.org/10.2478/mme-2018-0029

Sakthivelu, S., Meignanamoorthy, M., Ravichandran, M., Sethusundaram, P.P. (2019). Tribological behaviour of AA7075-ZrSiO4 composites synthesized by stir casting technique. Mech. Mech. Eng. 23, 198-201. https://doi.org/10.2478/mme-2019-0026

Sambathkumar, M., Sasikumar, K.S.K., Gukendran, R., Dineshkumar, K., Ponappa, K., Harichandran, S. (2021). Investigation of mechanical and corrosion properties of Al7075/Redmud metal matrix composite. Rev. Metal. 57 (1), e185. https://doi.org/10.3989/revmetalm.185

Senthamarai, K., Deepak, D., Saravanan, H., Gopikrishnan, C., Alagarsamy, S.V., Chanakyan, C. (2023). Investigations on the wire EDM characteristics of Al matrix composite using TOPSIS method. Mater. Today: Proc. 74 (1), 110-116. https://doi.org/10.1016/j.matpr.2022.12.130

Singh, J., Chauhan, A. (2019). A review of microstructure, mechanical properties and wear behavior of hybrid aluminium matrix composites fabricated via stir casting route. Sadhana 44, 16. https://doi.org/10.1007/s12046-018-1025-5

Suresh, S., Gowd, G.H., Deva Kumar, M.L.S. (2019). Mechanical properties of AA 7075/Al2O3/SiC nano-metal matrix composites by stir-casting method. J. Inst. Eng. India Ser. D. 100, 43-53. https://doi.org/10.1007/s40033-019-00178-1

Uros Stamenkovic., Svetlana Ivanov., Markovic., I., Milan Gorgievski, Božinović, K., Kovačević, A. (2023). The influence of the ageing temperature on different properties of the EN AW-7075 aluminium alloy. Rev. Metal. 59 (1), e238. https://doi.org/10.3989/revmetalm.238

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.