Effect of the post heat treatment on the sliding wear resistance of a nickel base coating deposited by high velocity oxy-fuel (HVOF)

DOI:

https://doi.org/10.3989/revmetalm.2007.v43.i1.51Keywords:

Thermal spray coating, Comonoy 88, heat-treatment, oxyacetylene flame, wear performanceAbstract

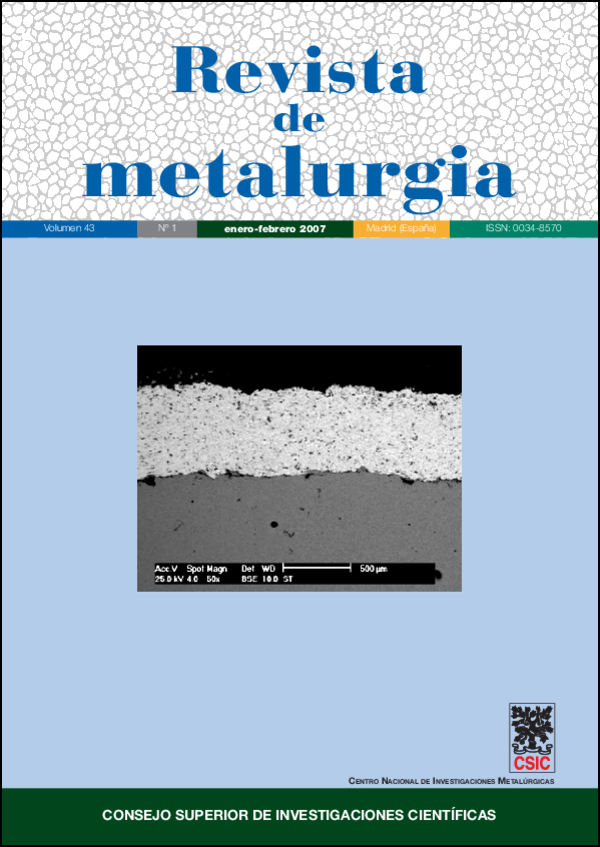

In the present research, a nickel base coating was deposited on an AISI 1020 substrate by using high velocity oxy-fuel technique (HVOF). The coating was subsequently post heat -treated by means of an oxyacetylene flame. For the conditions evaluated in the present study, it was found that the CTT coating has 1,15 better wear resistance for the smaller level of the applied load and nearly 50 times for the highest level of the applied load when compared to the STT coatings. These results have been attributed to a better distribution of the hard phases, better cohesion between particles and an increase in hardness, as consequence of the post heat treatment process. A severe wear regime was found for all the samples since the wear rates presented values which were higher than 1·10-5 mm3/m. For the CTT coatings, the wear mechanism was mainly due to the adhesion and oxidation phenomena, meanwhile for the steel counterpart mechanisms such oxidation, grooving and three body abrasion were observed.

Downloads

References

[1] J. Matejicek, S. Sampath, Gnaeupel-Herold. Y H. Prask, Proc. ITSC 2000, Thermal Spray Conference, Montreal, Canada, 2000, pp. 351-354.

[2] Wei-Min Zhao, Yong Wang, Li-Xiang Dong, Kai –Yuan Wu y Jin Xue, Surf. Coat. Technol. 190 (2005) 293-298. doi:10.1016/j.surfcoat.2004.04.057

[3] G. Fillion, Welding Journal 78, (1994) 365-368.

[4] P. Pisacka y P. Chraska, Proc. ITSC 2000, Thermal Spray Conference, Montreal, Canada, (2000) 449-469.

[5] D. Guo, Surf. Coat. Technol. 73 (1995) 73-78. doi:10.1016/0257-8972(94)02364-6

[6] M. Rodriguez, Trabajo de Maestría en Metalurgia y Ciencia de los Materiales, (2002), Universidad Central de Venezuela, Venezuela.

[7] L. Gil, M. Rodríguez y M. H. Staia, J. Thermal Spray Technol. 11 (2002) 95-99. doi:10.1361/105996302770349023

[8] V. Stoica, R. Ahmed y T. Itsukaichi, Surf. Coat. Technol. 199 (2005) 7–21. doi:10.1016/j.surfcoat.2005.03.026

[9] E. Fernandez, M. Cadenas, R. Gonzalez, C. Navas, R. Fernandez y J. Damborenea, Wear 259 (2005) 870-875. doi:10.1016/j.wear.2005.02.063

[10] G. Castro-Regal, A. Fernandez-Vicente y M. A. Martinez, Rev. Metal. Madrid 41 (2005) 212-219.

[11] G. Muñiz, A. Conde, B.J. Fernández, R. Varela y J. De Damborenea, Rev. Metal. Madrid 39 (2003) 443-451.

[12] A. Thomas, Surf. Eng. 3 (1987) 117-122.

[13] Linda Gil y M.H.Staia, Surf. Coat. Technol. 120-121 (1999) 423-429. doi:10.1016/S0257-8972(99)00494-6

[14] D. Tabor, Proc. Inst. M&. Engr. 181 (1966-67) 236-237.

[15] L. Samuels, E. Doyle y E. Turley, Fundamentals of Friction and Wear of Materials (Ed. D.A. Rigney), ASM, Materials Park, OH, EE. UU., 1981, pp. 13-41

[16] T. Quinn, D. Rowson y J. Sullivan, Wear 65 (1980) 1-20. doi:10.1016/0043-1648(80)90002-2

[17] E. Borgioli, F. Galvanetto, T. Galliano, T. BACCI, Wear (2005) (in press).

[18] J. Archard, J.Appli Physics 24 (1953) 981-988

[19] F. Bowden y D. Tabor, The friction and lubrication of solids, Clarendon Press, 2, Inglaterra, (2001) pp. 285-287.

[20] J. Archard, “Wear theory and mechanisms” Wear Control Handbook, New York, American Society of Mechanical Engineers,1980, pp. 35-80.

[21] N. Welsh, Philosophical Transaction of Royal Society 257 (1965) 31-50. doi:10.1098/rsta.1965.0001

[22] Y. Wang, I. Lei y J. Liu, Wear 231 (1999) 1-37. doi:10.1016/S0043-1648(99)00115-5

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2007 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.