Mechanical properties of AZ31 alloy processed by a green metallurgy route

DOI:

https://doi.org/10.3989/revmetalm.1315Keywords:

Eco-Magnesium, AZ31, Microstructure, Mechanical propertiesAbstract

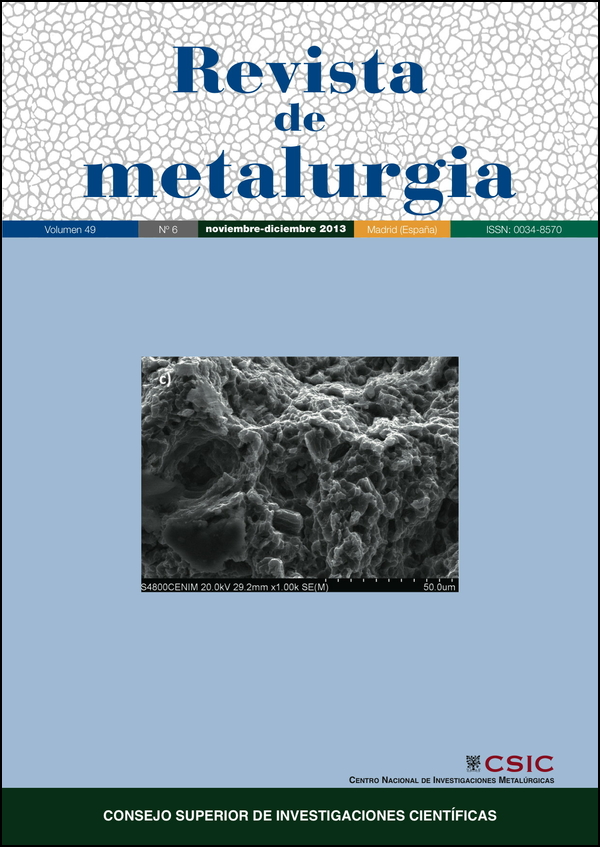

Recently it has been proved that molding of defect-free components of various commercial alloys of magnesium can be carried out succesfully when small amounts of CaO are added to the melt, making unnecessary the use of SF6 coverage. In the case of AZ alloys, this process also remarkably improves their mechanical properties not only by the greater cleaning of alloys but also by the formation of CaAl2 phase. This work, part of the Green project Metallurgy (http://www.green-metallurgy.eu) funded by the European Union (LIFE+2009), studies the influence of different CaO additions on the microstructure and mechanical properties of AZ31 Eco-Mg alloy. The alloy was processed by a conventional route involving extrusion of as-cast rods as well as by a powder metallurgy route (PM) using chips as starting material. The objective was to analyze the viability of recycling machining chips to manufacture components for the automobile industry and transportation in general, because of its low cost and environmental impact. It has been demostrated that alloys processed from chips exhibit the highest tensile stress values, close to 320 MPa.

Downloads

References

[1] J.K. Lee y S.K. Kim, Trans. Nonferrous Metals Society of China 21, 1 (2011) 23-27. http://dx.doi.org/10.1016/S1003-6326(11)61054-6

[2] S.K. Kim, J.K. Lee, Y. Yoon y H. Jo, J. Mater. Process. Tech. 187-188 (2007) 757-760. http://dx.doi.org/10.1016/j.jmatprotec.2006.11.172

[3] (http://www.green-metallurgy.eu): © 2011 Green Metallurgy Innovation.

[4] J.K. Lee, H. Jo y S.K. Kim, Rare Metals 25 (2006) 155-159. http://dx.doi.org/10.1016/S1001-0521(08)60072-8

[5] G. Levi, S. Avraham, A. Zilverov y M. Bamberger, Acta Mater. 54 (2006) 521-530. http://dx.doi.org/10.1016/j.actamat.2005.09.023

[6] Y. Nan Zhang, D. Kervokov, L. Jian, E. Essadiqui y M. Medraj, Intermetallics 18 (2010) 2.404-2.411.

[7] Magnesium and Magnesium alloys, ASM Specialty Handbook, Ed. M.M. Avedesian y H. Baker, ASM International, 1999, p. 172.

[8] S. Cabeza Sánchez, Máster Oficial en Materiales Estructurales para las Nuevas Tecnologías, URJC y UC3M, Junio, 2010.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2013 Consejo Superior de Investigaciones Científicas (CSIC)

This work is licensed under a Creative Commons Attribution 4.0 International License.

© CSIC. Manuscripts published in both the printed and online versions of this Journal are the property of Consejo Superior de Investigaciones Científicas, and quoting this source is a requirement for any partial or full reproduction.

All contents of this electronic edition, except where otherwise noted, are distributed under a “Creative Commons Attribution 4.0 International” (CC BY 4.0) License. You may read the basic information and the legal text of the license. The indication of the CC BY 4.0 License must be expressly stated in this way when necessary.

Self-archiving in repositories, personal webpages or similar, of any version other than the published by the Editor, is not allowed.